SLA 3D Printing Service Supplier-Custom SLA Printed Parts-Full-Linking

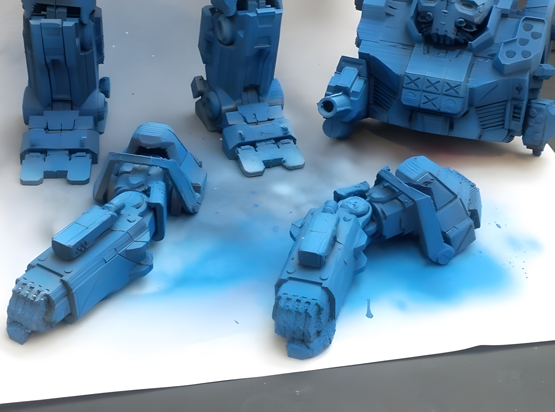

SLA is a pioneering 3D printing technology,known for its precision and smooth surface finish, SLA is ideal for creating detailed prototypes and intricate designs.

https://www.fulllinking.com/product/Stereolithography-SLA.html

What is Stereolithography (SLA)?

Stereolithography (SLA) is a pioneering 3D printing technology that uses a UV laser to cure liquid resin into solid objects. Known for its precision and smooth surface finish, SLA is ideal for creating detailed prototypes and intricate designs.

SLA Capabilities

High Precision

Build Size

Capable of creating parts up to 500 x 500 x 500 mm, suitable for a variety of applications.

Advantages of SLA

Superior Surface Finish

Rapid Prototyping

Materials

Plastics: Castable Resins,Flexible Resins,Tough Resins,Standard Resins

What Finishes are Available for SLA?

-

Post-Curing

After printing, SLA parts can undergo UV post-curing to enhance their strength and stability, ensuring better performance in functional applications.

-

Sanding and Polishing

Similar to FDM, SLA parts can be sanded and polished to achieve a high-gloss finish, making them suitable for display models.

-

Painting

SLA parts can be painted with specialty resin paints or acrylics, allowing for vibrant colors and detailed finishes.

-

Clear Coating

Applying a clear coat can enhance the surface finish and provide additional protection against scratches and UV damage.

Related products

-

EI-lamination with air gap

Contact UsThe gap sizes of transformer lamination core can be customized.

-

ATLAS COPCO 1629095101 STRAINER

Contact UsWe are ATLAS COPCO 1629095101 STRAINER supplier and provide replacement parts for major air compressor manufacturers. Please feel free to contact us at henry.guan@foxmail.com with any questions of the

-

Full Shift Cylinder (Tie Rod Type/Thread Type)

Contact UsWidely used for moving whole part of machines with low speed.

-

Yaw pitch gear

Contact UsWind turbine gears are an indispensable part of wind turbines. Their function is to convert the rotation speed of the wind rotor into the speed required by the generator, thereby generating electricity. The function of wind turbine gears is not simply to transmit power, but also involves the efficiency, reliability and life of wind turbines. It can improve power generation efficiency, stabilize operation, extend life, and reduce maintenance costs. With the continuous development of wind power generation technology, the role of wind turbine gears will become more and more important.

Reviews

There are no reviews yet.