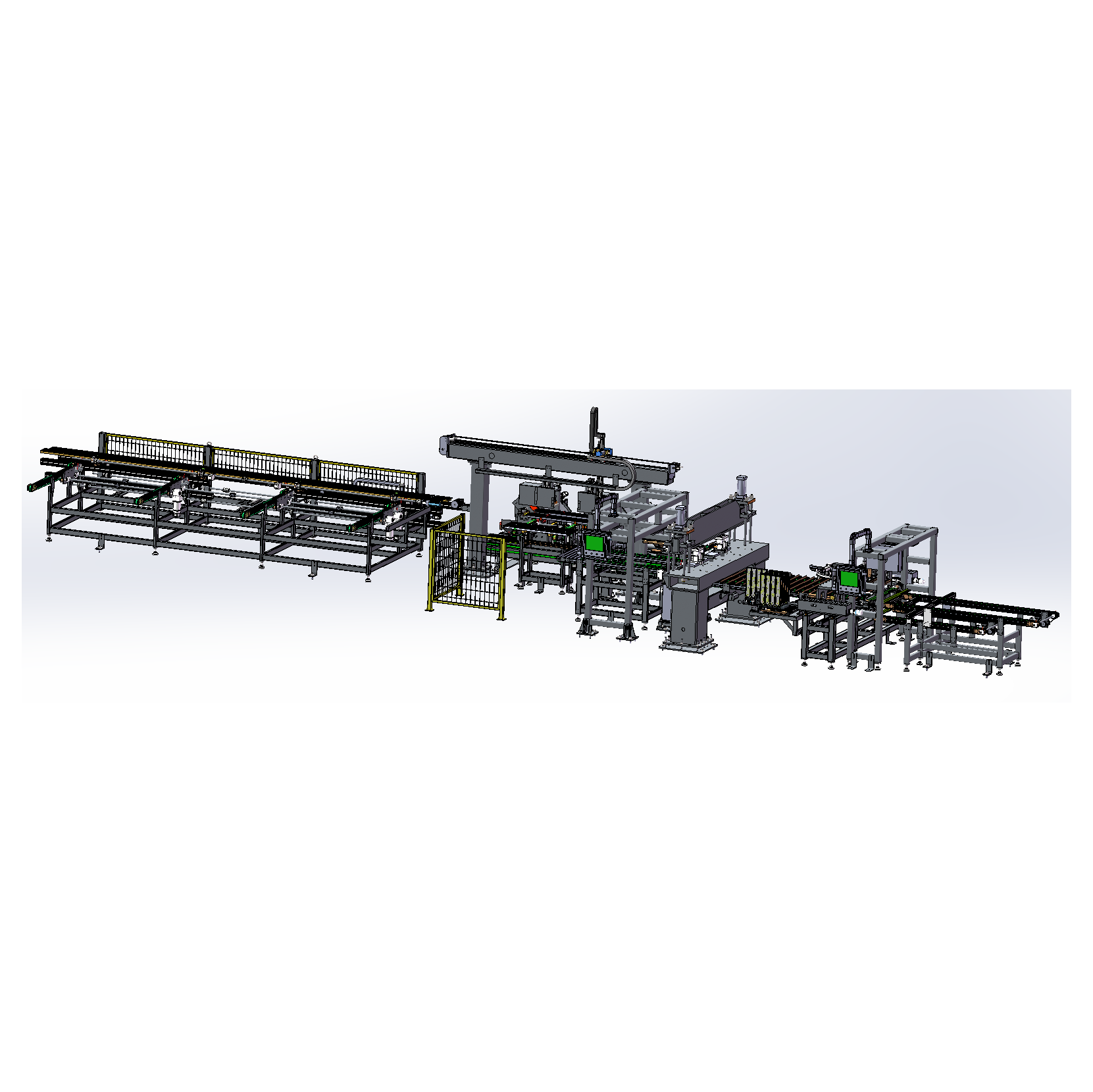

CLW-7000 automatic stamping production line of photovoltaic frame

CLW-7000 automatic stamping production line of photovoltaic frame is the 7th generation product launched by our company in 2025.

https://www.calowenauto.com/clw-7000-automatic-stamping-production-line-of-photovoltaic-frame.html

CLW-7000 automatic stamping production line of photovoltaic frame is the 7th generation product launched by our company in 2025.After more than 1 year of unremitting efforts,accumulation and reference,the company's R&D team has successfully developed anew generation of automatic stamping production line of photovoltaic frame,which has been significantly improved in production efficiency,product quality,energy saving and environmental protection, intelligent control and other aspects compared with the previous generation of production line.

Technical parameters

|

Name |

Automaticstampingproduction lineofphotovoltaicframe (longframe) |

Automaticstampingproduction lineofphotovoltaicframe (shortframe) |

|

Model |

CLW-25 |

CLW-15 |

|

Processinglengthrange(mm) |

1600~2500 |

990~1500 |

|

Processingsectionrange(mm) |

Bsidewidth:30-40,Csidewidth:10-35 |

|

|

Workingbeat(s) |

≤1.5 |

≤1.5 |

|

Angelaccuracy(°) |

±0.1 |

±0.1 |

|

Cuttinglengthaccuracy(mm) |

±0.15 |

±0.15 |

|

Qualifiedrateofprocessing |

99.8% |

99.8% |

|

Staffing(person/station) |

2.5 |

2.5 |

|

Ratedpower(kw) |

24 |

24 |

|

Externaldimensions(mm) |

16000×6000×2850 |

16000×6000×2850 |

Product advantages

1. The feeding method of sawing unit adopts the pulling material system,which improves the adaptability for twisted profiles.

2. The feeding of sawing unit is driven by electric cylinder,which effectively improves the processing quality of the workpiece.

3. The stamping molds only need to replace the punch head and inserted plate,which effectively reduces the costs.

4. Intelligent detection including length,mounting hole,bending,twisting,aluminium angle and water leakage hole detection.

5. Five sets of aluminium angle cartridges are set on one side of short frame stamping unit,and the aluminium angle capacity is greatly increased.

6. The finished products and defective products are automatically separated by upper and lower double-layer conveyor belt.

Related products

-

3MK2310B CNC Automatic Outer Ring Track Grinder for Tapered Roller Bearing

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 2100mm*1750mm*2030mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board -

NEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Contact UsNEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

-

Optimizing Cross Cut Saw MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

Reviews

There are no reviews yet.