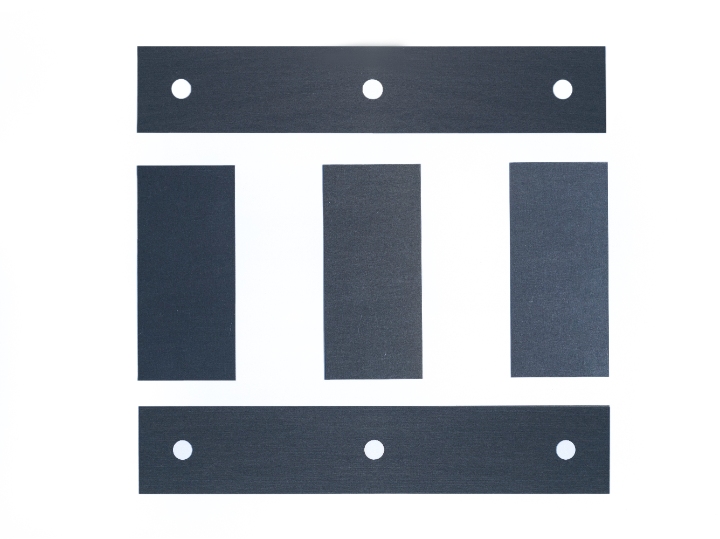

Strip Lamination

Adopting high quality materials for precision manufacturing. Can meet the high quality requirements of customers. The materials, sizes, shapes and specifications of the products are customized according to customers’ needs.

Adopting high quality materials for precision manufacturing. Can meet the high quality requirements of customers. The materials, sizes, shapes and specifications of the products are customized according to customers' needs.

Related products

-

SLA 3D Printing Service Supplier-Custom SLA Printed Parts-Full-Linking

Contact UsSLA is a pioneering 3D printing technology,known for its precision and smooth surface finish, SLA is ideal for creating detailed prototypes and intricate designs.

-

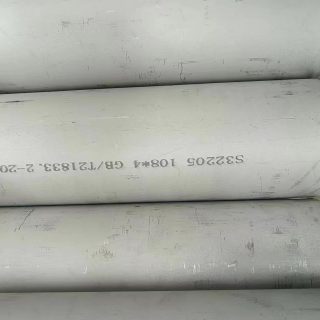

Duplex S32205 Seamless Pipe ASTM A790 Annealed Pickled

Contact UsSpecification: ASTM A790/A790M

Name: Duplex SS S32205 Seamless Pipe

Grade:S32205

Process: Seamless

Delivery Condiction:

1. Annealed, Pickled

2. Bright Annealed -

Yaw pitch gear

Contact UsWind turbine gears are an indispensable part of wind turbines. Their function is to convert the rotation speed of the wind rotor into the speed required by the generator, thereby generating electricity. The function of wind turbine gears is not simply to transmit power, but also involves the efficiency, reliability and life of wind turbines. It can improve power generation efficiency, stabilize operation, extend life, and reduce maintenance costs. With the continuous development of wind power generation technology, the role of wind turbine gears will become more and more important.

-

Inch Miniature Ball Bearings

Contact UsPrecision:ABEC-1,ABEC-3,ABEC-5

Material:Chrome steel ,stainless steel

Lubrication Brand:Kyodo or Shell

OEM service:Custom Bearing size,logo,packing

Certifications:ISO9001 or IATF 16949

Payment terms:T/T, L/C, D/A,D/P,Western Union

Capacity:5 millon per month

Delivery time:1 week for sample, 30-45days for mass production

Packing details:plastic tube+plastic bag (or box)+carton

Reviews

There are no reviews yet.