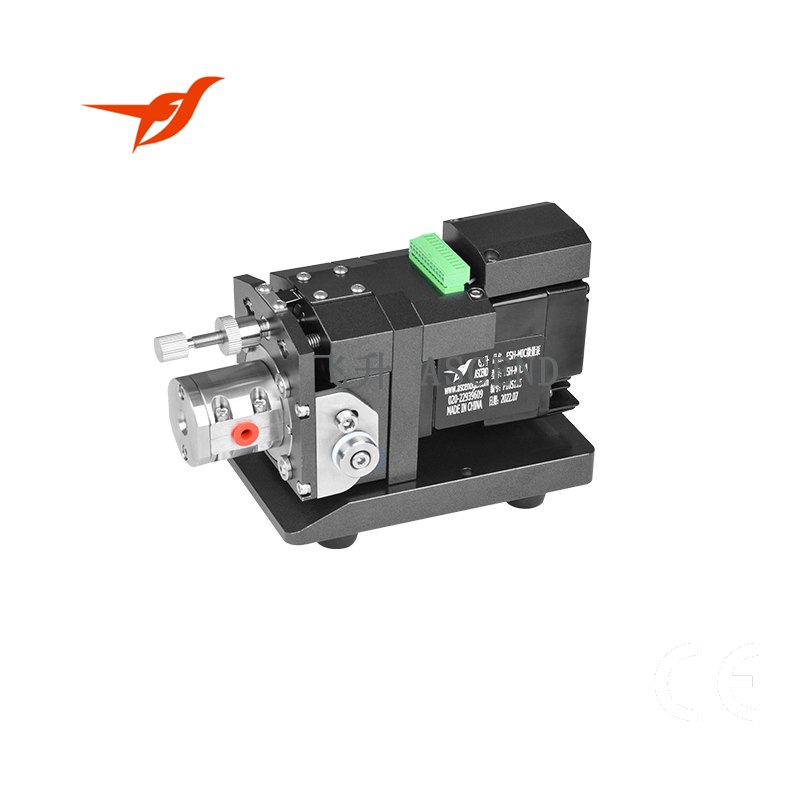

FSH-MIC Micro Fluid Injection / Cleaning Pump

FSH-MIC high-precision fluid point-to-liquid/cleaning pump integrates the driver chip into the motor, no controller is needed, only external IO signal is needed to trigger, and the point/subassembly can be completed according to the specified program. The system design is flexible, convenient for system integration, and reduce cost.

https://www.ascendtechs.com/FSH-MIC-A-serial-Micro-Fluid-Injection-Cleaning-Pump.html

FSH-MIC high-precision fluid point-to-liquid/cleaning pump integrates the driver chip into the motor, no controller is needed, only external IO signal is needed to trigger, and the point/subassembly can be completed according to the specified program. The system design is flexible, convenient for system integration, and reduce cost.

System Features

Best choice for OEM

Integration of motor and drive

No controller required

Light and compact module

Best value

High efficiency and high precision (Up to ±0.3%CV)

Continuous measurement

Specifications

Technical Parameters

Typical Applications

Cleaning solutions metering (chip, screen, lithium battery, etc.)

Biochemical reagent metering.

Flavoring essence addition

Batching reagent addition

Related products

-

3MK144 CNC automatic outer ring track grinder for ball bearing

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 1900mm*1350mm*1880mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board -

FS-V-F240 Injection valve

Contact UsFS-V-F240 series drip-proof valve is suitable for direct injection of lithium battery which can efficiently avoid liquid dropping and hanging.

-

SWFL Vertical-Shaft Pulverizer

Contact UsThe vertical shaft pulverizer is widely applicable to feed, flour, chemical, pharmaceutical, starch and other industries, which achieve ultra-fine grinding to meet the requirements of the subsequent p

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

Reviews

There are no reviews yet.