MA-(4~16MM)×2200MM Automatic Steel Coil Slitting Line

MA-(4~16MM)×2200MM Automatic Steel Coil Slitting Line includes: uncoiler, guiding device, uncoiling tension device, coil head shearing.

https://www.mazsmachine.com/MA-4-16MM-2200MM-Automatic-Steel-Coil-Slitting-Line.html

General Introduction

– MA-(4~16MM)×2200MM Automatic Steel Coil Slitting Line includes: uncoiler, guiding device, uncoiling tension device, coil head shearing, feeding table, looper, disc shearing, guiding roller, machine row transfer roller, clamping device, constant tension coiler, scrap rewinding machine, recoiler, etc.

– MA-(4~16MM)×2200MM Automatic Steel Coil Slitting Line is suitable for coil strip thickness (4-16)mm; while strip width is changeable: 600mm. 1000mm, 1250mm, 1600mm, 1800mm 2200mm and so on.

Detailed Technical Data

– Material of coils: HR/CR carbon steel such as Q235, galvanized plate, colored steel plate etc

– Strip thickness: (4~16)mm

– Metal Coil Slitter Strip width: 800~2200mm

– Coil Slitting Machine Max.coil weight: 40000kgs

– Diameter of leveling rollers & tensioning roller: Φ230

– Diameter of slitter shaft: Φ360

– Metal Coil Slitter Disc cutters: 6CrW2Si, HRC54°~56°, OD600mm x ID360mm x T50mm.

– Diameter of recoiler block: Φ760mm

– Coil Slitting Machine Separating discs: 65Mn, OD250 x ID110 x T10/20mm

– DC motors for slitter and recoiler: 200KW, 250KW.

– Slitting speed: (0~30)m/min, adjustable

Machine Main Components

– Feeding trolley – single-arm feeding machine, coil leading device – tilting platform – looper 1 – rectification – disc shear – waste scrap winding – looper 2 – pre-slitting, tension machine, length measuring roller – recoiling – unloading trolley – hydraulic control – electrical control

Specification Form

|

Model |

Thickness |

Coil width |

Coil Weight |

Finished slit |

Max Slitting speed |

|

MA-16×2200 |

4-16mm |

800-2000mm |

Max 40T |

Min. 100mm |

30m/min |

|

Note: The data in the form just as reference according to general ranges, we always design and make each sheet slitting line according to each customer's specific requirements, so each customer can buy his own well-content coil slitting machine from us. |

|||||

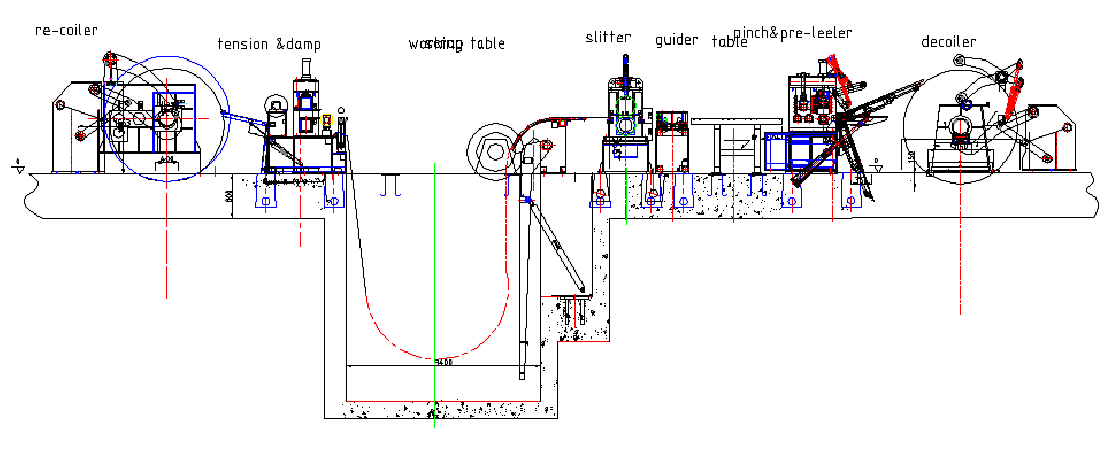

Production Line Flowing Chart

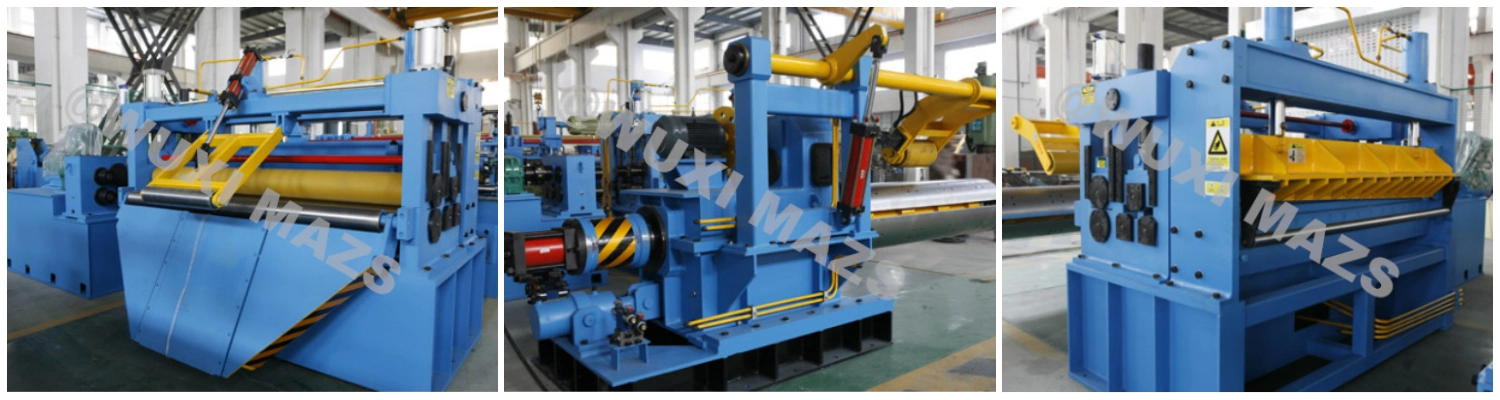

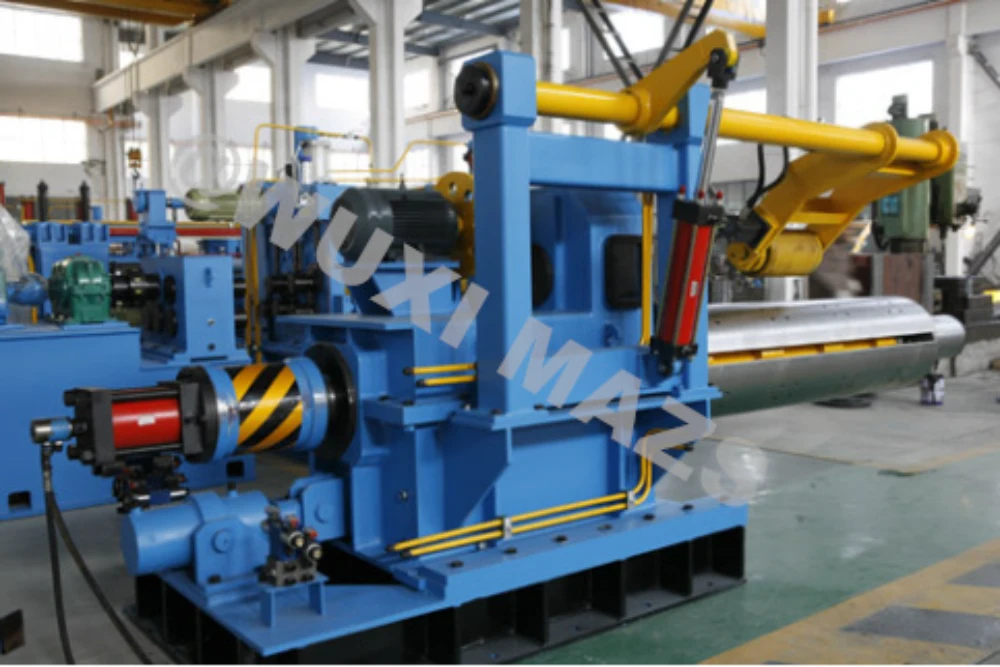

Machine Photo for Reference

Loading and Packing

Machine will be fixed inside container by steel wire and special PET strap to be , in order to make sure all parts will not move during transportation and avoid any kinds of damage of machine and container.

Our Service and Features

– 1. Design: MAZS have a matured and experienced technical team with rich experience to develop and design the machines according to customer's demand and requirements.

– 2. This is a very perfect and durable equipment. MAZS have more than 20 years experiences in this field.

– 3. This kind of machine has superior quality and reliable service. It has high accuracy and easy operation.

– 4. MAZS supply technical support (both before, during and after sales), production, installation, commissioning and maintenance service to all customers.

– 5. Our product has been exported to many regions and won high reputation because of the high quality reasonable price and reliable service, quick action for after sale service.

Related products

-

25KVA/20KW 50HZ Diesel Generator With Cummins Engine

Contact UsAs a 25KVA 20KW diesel generator with Cummins engine exporter,EMEAN POWER provides reliable and efficient 25KVA 20KW silent diesel generators running at 50Hz.

-

Used Muratec 861 Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

-

7000A 12V&24V Jump Starter for Truck Starting in -40°C

Contact UsConquer the coldest of temperatures with our Arctic Warrior 7000A 12V&24V Jump Starter.

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

Reviews

There are no reviews yet.