Custom Fin Forming Machine and Fin Molds

Fins are the basic components of heat exchanger, on which heat transfer to be finished depends. Main fin types: offset fin, straight fin, perforated fin, louvered fin, corrugated fin. High Speed Automatic Fin Forming Machine and Fin Molds is the special equipment to produce all kinds of Heat Exchanger Fins. With different fin molds, Heat Exchanger Fin production machine can automatically and stably produce all kinds of aluminum fins, Copper Fins and SS Fins.

Packaging: Pallet/Case

Productivity: 250 Sets/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 250 Sets/Month

Port: Shanghai

Payment Type: T/TIncoterm: FOB,CFR,CIF,EXW,FCA

-

Selling Units:Set/Sets

-

Package Type:Pallet/Case

-

Fins are the basic components of heat exchanger, on which heat transfer to be finished depends. Main fin types: offset fin, straight fin, perforated fin, louvered fin, corrugated fin. High Speed Automatic Fin Forming Machine and Fin Molds is the special equipment to produce all kinds of Heat Exchanger Fins. With different fin molds, Heat Exchanger Fin production machine can automatically and stably produce all kinds of aluminum fins, Copper Fins and SS Fins. The fins via our fin forming machine have the advantages of high precision, good appearance and low processing cost. Heat exchanger fin production machine mainly include Automatic Feeding Material Device, High Speed Automatic Fin Forming Machine, Radiator Fin Forming Moulds, Automatic Fin Cutter/ Fin Servo Cutting Systemr. Better-Tech specializes in supplying the full set of fin forming solution. In the sereis of Fin Machine and fin molds, we uphold customized service to meet cllients' fin special design and demands. Please supply your fin specification or fin drawing, we can supply the optimized configuration to make you produce your desired heat exchanger fins.

-

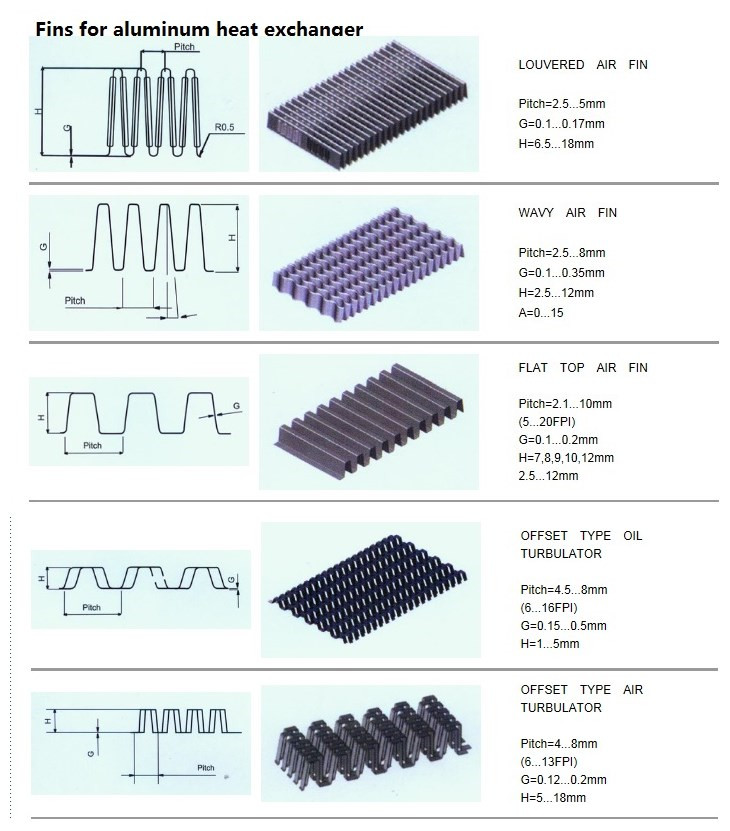

Heat Exchanger Fin Type:

-

-

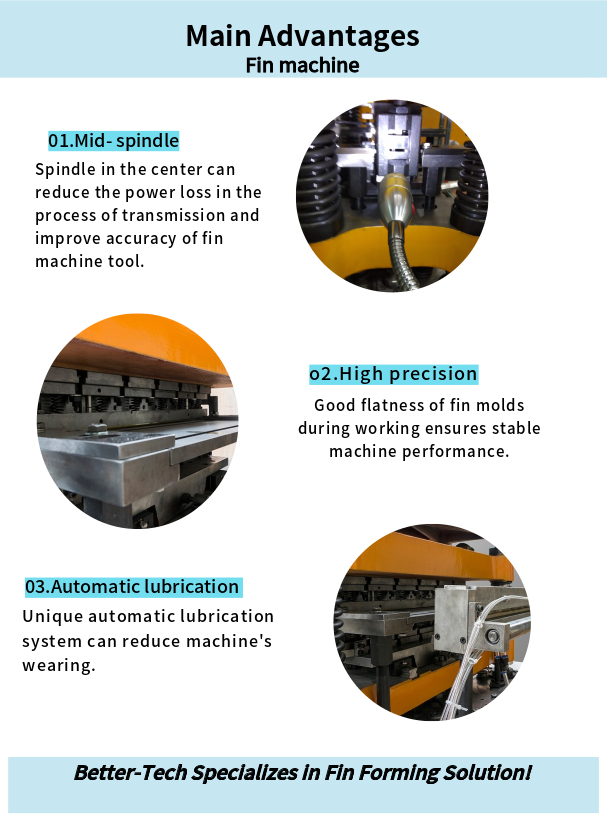

Better Tech Fin Machine's Advantages:

-

Related products

-

PP PE HDPE LDPE LLDPE Film Waste Recycling Pelletizing Machine Pelletizer Granulator

Contact UsThis is multifunctional small pelletizing line. It is used to recycle various leftovers, such as PP, PE, HDPE, LDPE, PVC, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

KNIFE SHARPENER 220V STAINLESS STEEL MULTI-PURPOSE ELECTRONIC KNIFE SHARPENER

Contact Ushttps://www.cnhfprecision.com/news/5820.html https://www.cnhfprecision.com/news/5927.html https://www.cnhfprecision.com/news/6059.html https://www.cnhfprecision.com/news/6058.html https://www.cnhfprecision.com/news/6415.html https://www.cnhfprecision.com/news/6558.html https://www.cnhfprecision.com/news/6608.html Product Name Knife Sharpener Rated Voltage 220v Power 40W Material Aluminium die-casting housing Color Silver, Red or Customized Certification CE / EU Room Space Desktop, Countertop, Kitchen Applicable Knife Type Work for all steel knives Application 1. patented spring loaded knife2.sharpening wheels with 20 ceramic pins3.electrically driven sharpening …

KNIFE SHARPENER 220V STAINLESS STEEL MULTI-PURPOSE ELECTRONIC KNIFE SHARPENERRead More

-

FSH-FMI2020-A Standard Single Double Channel Fluid Injection

Contact UsFSH – FMI2020 – A standard series is the high-precision fluid dispensing / refilling system consisting of a digital control box, stepper motor and one to two high precision rotary ceramic pump modules driven by step motor.

-

Capacity 1500ML Carbonated Drink Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1500ml

Bottle Type: CSD bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export.

Reviews

There are no reviews yet.