VMC 1580 Vertical Machining Center

The machine is suitable for automobile and locomotive parts production, aviation, communication electronics, various types of precision mold processing and other fields.

https://www.josencnc.com/VMC-1580-CNC-Vertical-Machining-Center.html

The machine is suitable for automobile and locomotive parts production, aviation, communication electronics, various types of precision mold processing and other fields. The bed adopts high rigidity structure, which makes the internal force structure more optimized and ensures the rigidity and thermal stability of the whole machine. The spindle box adopts balance cylinder counterweight to avoid vibration when running at high speed.

1.This model is suitable for mass production of automobile and locomotive

parts, aerospace and communication electronics, automation parts processing, and

various types of precision mold processing.

2.The base, slide, table, column, spindle box and other major foundation

parts are made of high rigidity cast iron structure, and the internal

reinforcement bars are distributed in a mesh structure to ensure the high

rigidity of the foundation parts and the anti-bending and anti-vibration

performance.

3.The X and Y axes adopt heavy-duty 45mm roller rail, and the Z axis adopts

55mm roller rail, which makes the machine stronger in terms of load bearing

capacity and cutting performance, and the Y axis saddle adopts four-rail full

support, which is stable and reliable.

4.The spindle box adopts balance bar counterweight to ensure no shaking when

the spindle box is shifted quickly and to ensure the accuracy of movement.

5.The spindle is equipped with belt type 8000rpm as standard, no noise and

low vibration, suitable for high speed milling and tapping.

| ITEM | UNIT | CV-1580B |

| Travel | ||

| X-axis travel | mm | 1520 |

| Y-axis travel | mm | 800 |

| Z-axis travel | mm | 700 |

| Workable size | ||

| Working table size (X*Y) | mm | 1650×800 |

| Max.loading capacity of working table | kg | 1400 |

| Table T-slot size (width * number of slots * spacing) | number | 18x5x150 |

| Spindle | ||

| Spindle speed | rpm | 8000 |

| Spindle drive form | belt driven | |

| Spindle power | kW | 15/18.5 |

| Spindle bore specification | BT50 | |

| Distance from spindle to table surface | mm | 155-855 |

| Spindle feed | ||

| Rapid feed rate(X,Y,Z) | m/min | 20/20/20 |

| Cutting feed rate | mm/min | 10000 |

| Tool magazine | ||

| Tool magazine capacity | cutter arm type 24 | |

| Tool diameter/adjacent tool space | mm | Φ110/Φ200 |

| Max. Tool length | mm | 350 |

| Max. Tool weight | kg | 15 |

| Accuracy | ||

| Positioning accuracy | mm | ±0.01 |

| Reproduction accuracy | mm | ±0.005 |

| Others | ||

| Controller | 0i-MF/M80 | |

| Air pressure demand | kg/cm2 | 6 |

| Power demand | kVA | 50 |

| Machine weight | T | 11 |

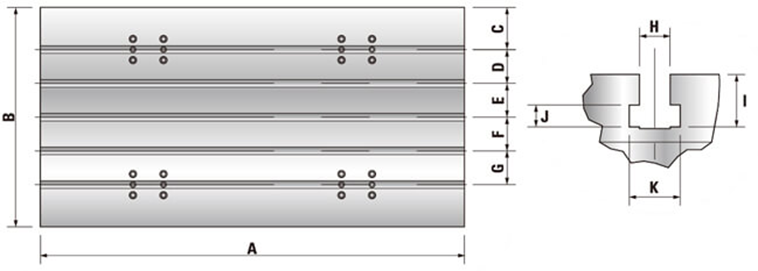

| Model | A | B | C | D | T-slot number |

| CV-1580B | 1650 | 800 | 100 | 150 | 5 |

Related products

-

Digital-control Fluid Injection / Filling system

Contact UsFSH-SK10 product series is one of the high efficiency, high precision and high reliability intelligent digital-control dispensing system in high flow. FSH-SK10 is the top choice for automated fluid filling systems and intelligent factory production lines with high-capacity injection pump.

-

Capacity 1500ML Carbonated Drink Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1500ml

Bottle Type: CSD bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

FS-V-F240 Injection valve

Contact UsFS-V-F240 series drip-proof valve is suitable for direct injection of lithium battery which can efficiently avoid liquid dropping and hanging.

-

Rotary kiln incinerator

Contact UsRotary kiln incineration systems are widely adopted in the international industrial waste treatment sector, holding an approximate market share of 85% in this field. They are also recommended by China’s Ministry of Science and Technology and the National Environmental Protection Agency as the preferred furnace type in the National Industrial Waste Treatment Technology Policy. These systems can simultaneously handle sludge, industrial waste and waste with high moisture content. Solid waste is conveyed into the rotary kiln where it undergoes moisture evaporation, volatilization, ignition, and complete combustion. Ash residue is discharged through an outlet at the kiln’s tail end, while the generated flue gas proceeds to a secondary combustion chamber. Here, it mixes with secondary combustion air to ensure thorough burning, leading to the safe and compliant discharge of exhaust gases. Key features of rotary kiln incinerators include their broad adaptability to various wastes, ease of operation and maintenance, and extended service life.

Reviews

There are no reviews yet.