https://www.gcmicgroup.com/CNC-Horizontal-Milling-Machine.html

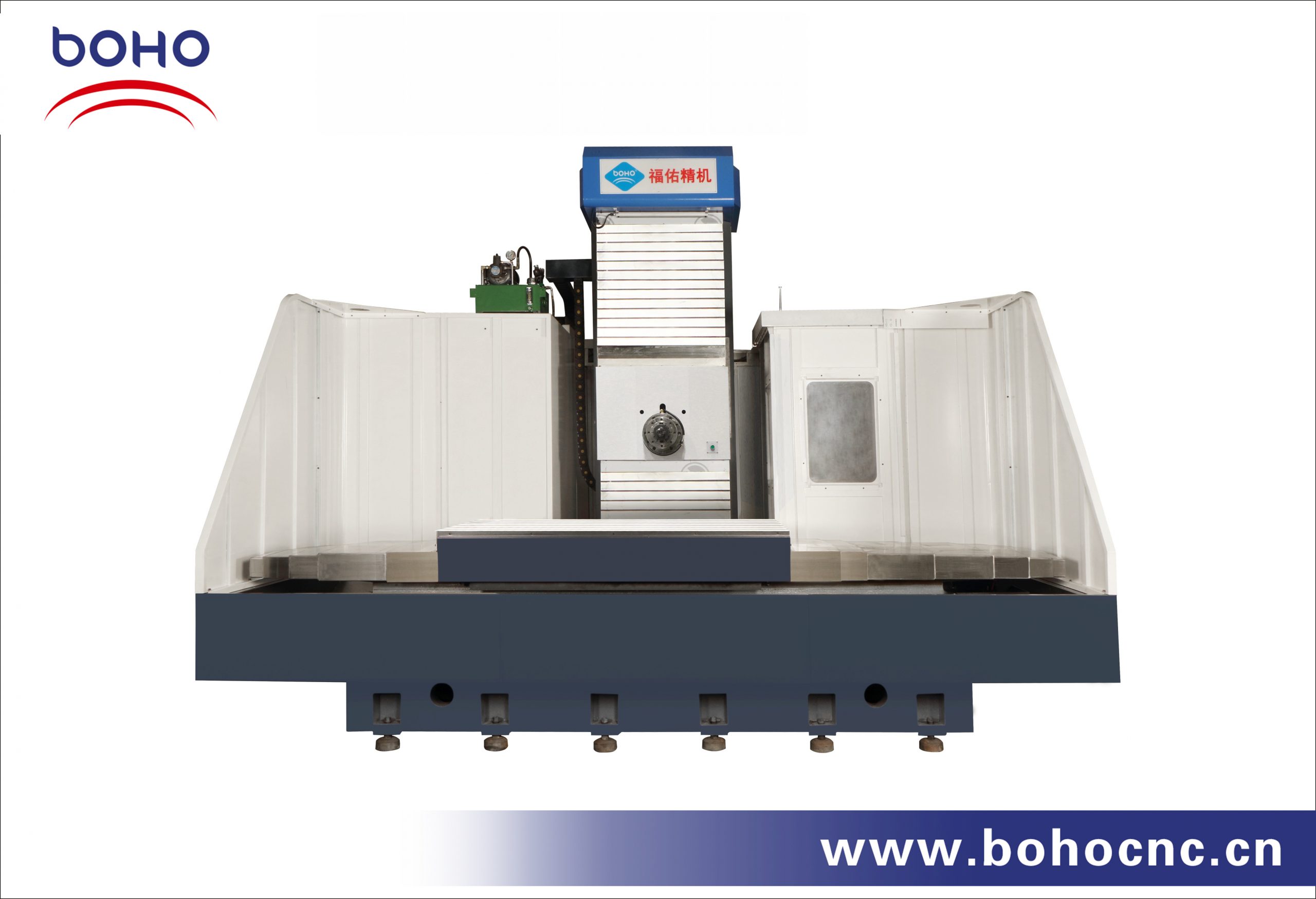

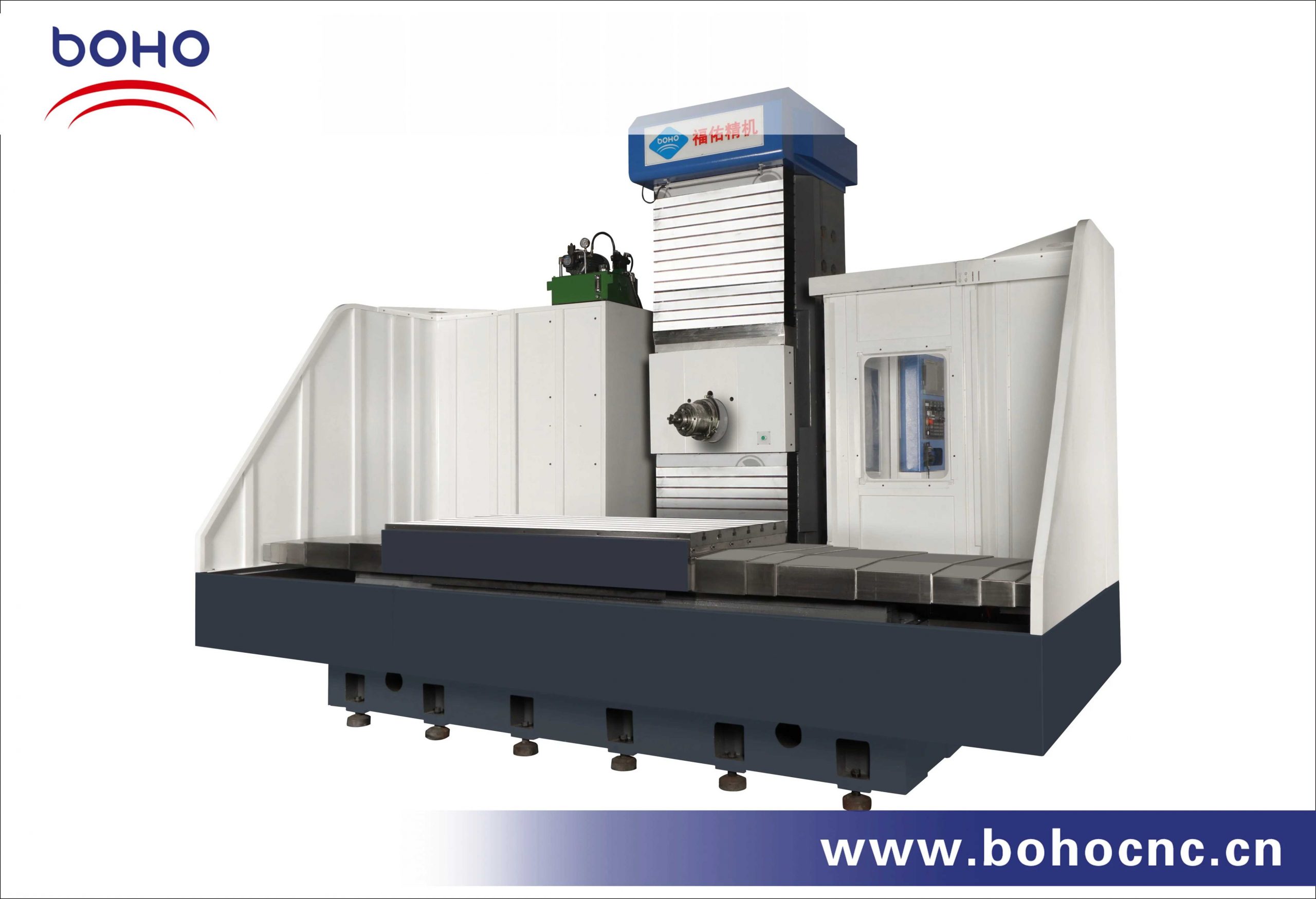

Heavy Duty Frame Opening Machine

Item |

Unit |

BH-W1812 |

BH-W2214 |

BH-W2616 |

|

| Processing Capacity | Work table size | mm | 1800*1200 | 2200*1400 | 2600*1600 |

| Travel of X/Y/Z axis | mm | 1900/1200/600 | 2300/1400/700 | 2600/1600/800 | |

| Travel of triangular table | mm | 500 | 600 | 700 | |

| Dis. spindle centre to worktable | kg | 60-1260 | 60-1460 | 60-1660 | |

| Triangular table size | mm | 1800*1000 | 2200*1200 | 2600*1400 | |

| Max. load capacity | kg | 6000 | 9000 | 12000 | |

| Milling Tool/Spindle | Spindle taper | No. | BT50(7:24) | ||

| Spindle speed | rpm | 3000 | |||

| Spindle motor power | kw | 15 | |||

| Servo Motor | X/Y/Z feeding rate | m/min | 10 | 8 | 8 |

| X-axis feed motor torque | N.m | 35 | 35 | 35 | |

| Y-axis feed motor torque | N.m | 35 | 35 | 35 | |

| Z-axis feed motor torque | N.m | 35 | 35 | 35 | |

| Size | Size | mm | 5500*3600*4000 | 6500*4000*4500 | 7500*4600*4800 |

| Weight | kg | 22000 | 26000 | 30000 | |

| CNC System | Standard: FANUC(Japan) | ||||

-

Steel

-

Stainless steel

-

Tool steels

-

Hot work die steel

-

Cold work tool steel

-

Plastic mold steel

-

Raw metal

-

Aluminum

-

Ferrous or non-ferrous metals

-

Cast iron

-

Mold plate

-

Other four-sided square metal

Related products

-

Optimizing Cross Cut Saw MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

FS-V-F240 Injection valve

Contact UsFS-V-F240 series drip-proof valve is suitable for direct injection of lithium battery which can efficiently avoid liquid dropping and hanging.

-

NEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Contact UsNEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

-

Used NSC Schlumberger GC14 Gilling Machine

Contact UsYear: 1996

Spinning production line

Mixed strip: GC15 barrel diameter 1000 * 1200mm, 1 head and 1 barrel, automatic barrel change

One stitch: GC14 cylinder diameter 1000 * 1200mm, 1 head and 1 barrel, with self leveling and automatic barrel changing

Two needles: GC14 cylinder diameter 700 * 1200mm, two heads and two barrels, automatic barrel changing

Three needles: GC14 cylinder diameter 600 * 1200mm, 4 heads, 2 barrels, automatic barrel change

According to your requirements, we can transform it into a suitable size for your production needs!

Reviews

There are no reviews yet.