https://www.gcmicgroup.com/CNC-Horizontal-Milling-Machine.html

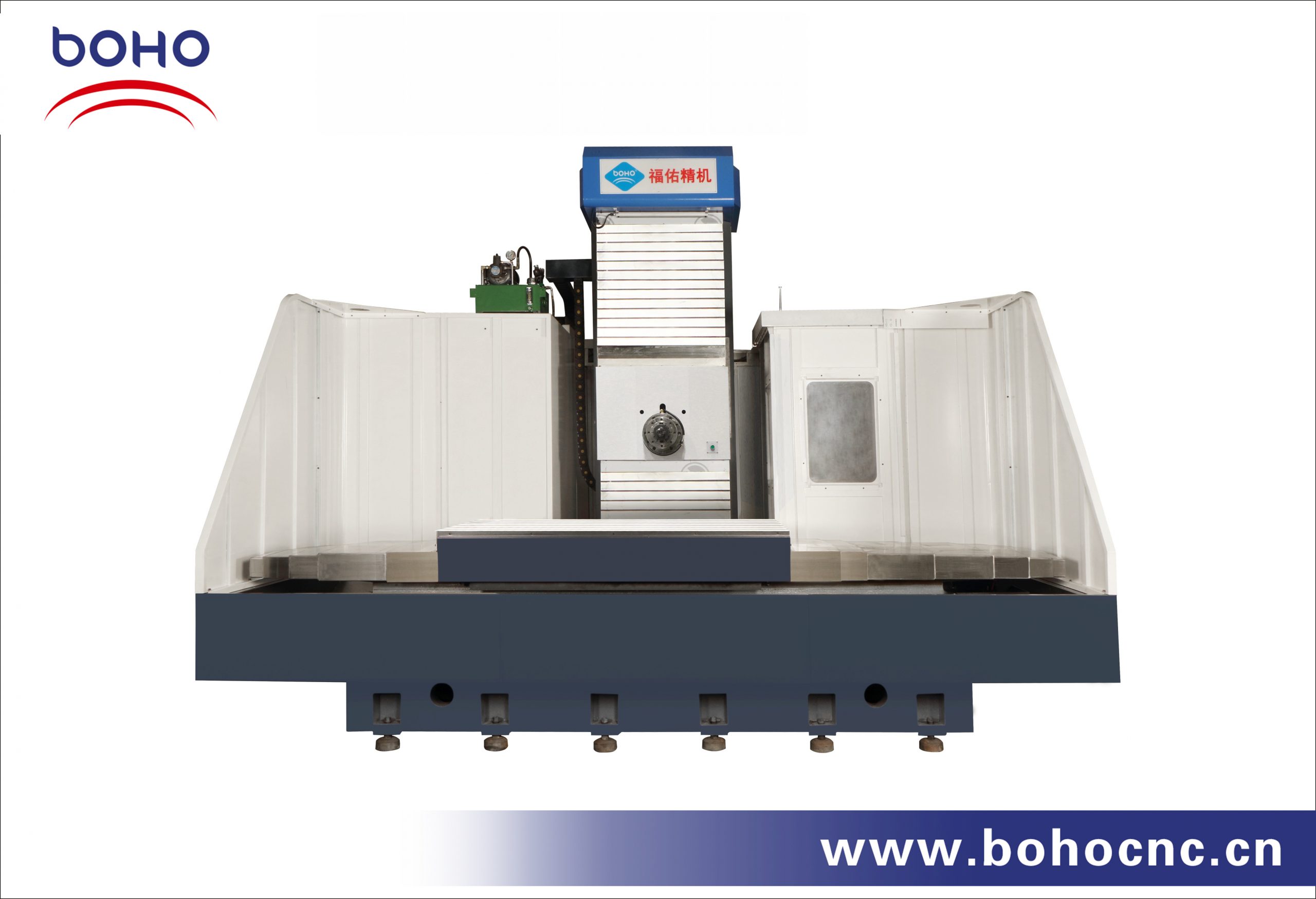

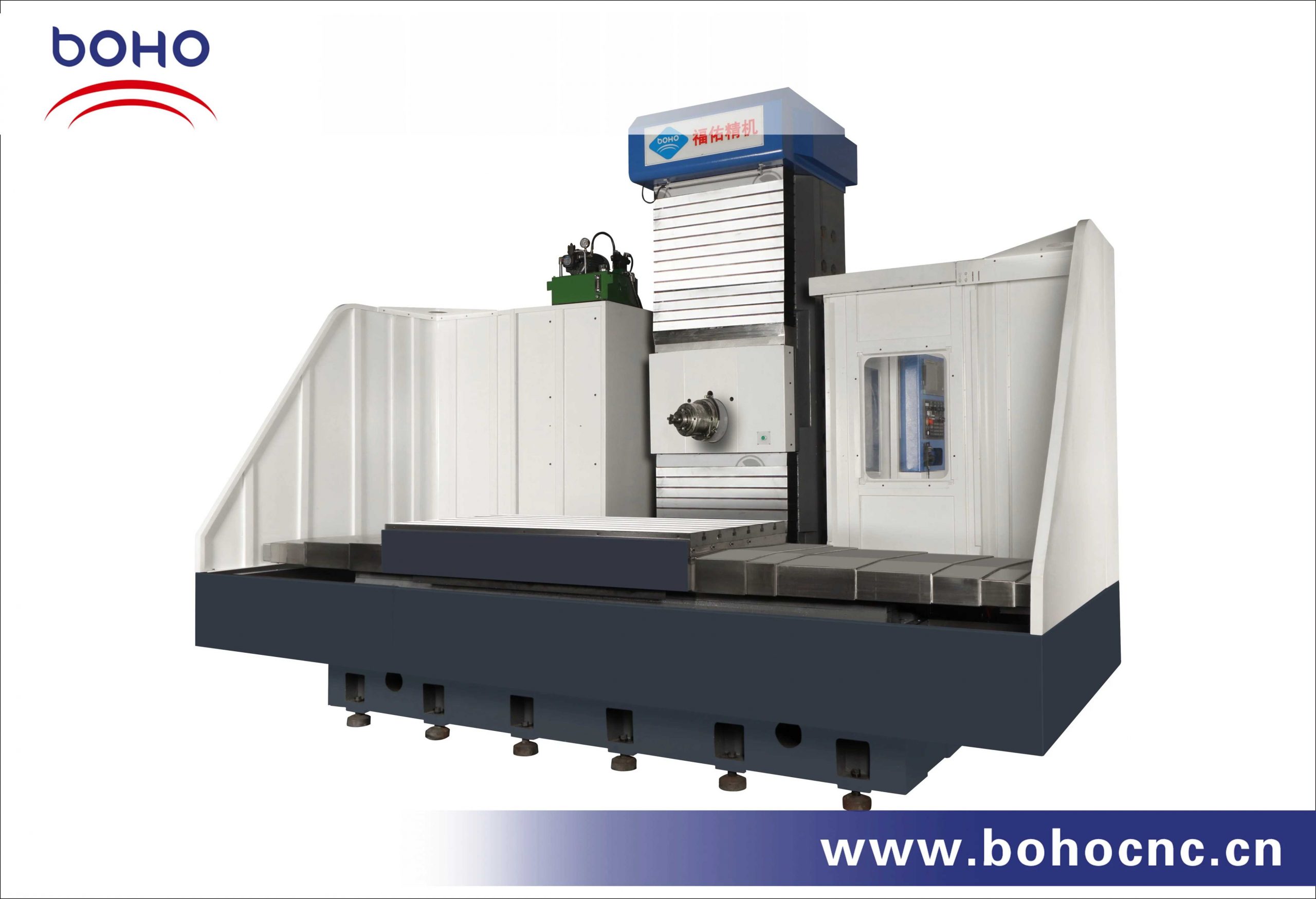

Heavy Duty Frame Opening Machine

Item |

Unit |

BH-W1812 |

BH-W2214 |

BH-W2616 |

|

| Processing Capacity | Work table size | mm | 1800*1200 | 2200*1400 | 2600*1600 |

| Travel of X/Y/Z axis | mm | 1900/1200/600 | 2300/1400/700 | 2600/1600/800 | |

| Travel of triangular table | mm | 500 | 600 | 700 | |

| Dis. spindle centre to worktable | kg | 60-1260 | 60-1460 | 60-1660 | |

| Triangular table size | mm | 1800*1000 | 2200*1200 | 2600*1400 | |

| Max. load capacity | kg | 6000 | 9000 | 12000 | |

| Milling Tool/Spindle | Spindle taper | No. | BT50(7:24) | ||

| Spindle speed | rpm | 3000 | |||

| Spindle motor power | kw | 15 | |||

| Servo Motor | X/Y/Z feeding rate | m/min | 10 | 8 | 8 |

| X-axis feed motor torque | N.m | 35 | 35 | 35 | |

| Y-axis feed motor torque | N.m | 35 | 35 | 35 | |

| Z-axis feed motor torque | N.m | 35 | 35 | 35 | |

| Size | Size | mm | 5500*3600*4000 | 6500*4000*4500 | 7500*4600*4800 |

| Weight | kg | 22000 | 26000 | 30000 | |

| CNC System | Standard: FANUC(Japan) | ||||

-

Steel

-

Stainless steel

-

Tool steels

-

Hot work die steel

-

Cold work tool steel

-

Plastic mold steel

-

Raw metal

-

Aluminum

-

Ferrous or non-ferrous metals

-

Cast iron

-

Mold plate

-

Other four-sided square metal

Related products

-

Oil-immersed transformer

Contact UsThe oil-immersed transformer is a new type of high-performance transformer with a more reasonable structure and better performance.

-

Digital-control Fluid Injection / Filling system

Contact UsFSH-SK10 product series is one of the high efficiency, high precision and high reliability intelligent digital-control dispensing system in high flow. FSH-SK10 is the top choice for automated fluid filling systems and intelligent factory production lines with high-capacity injection pump.

-

LFQ1300 Micro Computer Controlling Slitting Machine

Contact UsLFQ1300 Micro Computer Controlling Slitting Machine

-

Rotary kiln incinerator

Contact UsRotary kiln incineration systems are widely adopted in the international industrial waste treatment sector, holding an approximate market share of 85% in this field. They are also recommended by China’s Ministry of Science and Technology and the National Environmental Protection Agency as the preferred furnace type in the National Industrial Waste Treatment Technology Policy. These systems can simultaneously handle sludge, industrial waste and waste with high moisture content. Solid waste is conveyed into the rotary kiln where it undergoes moisture evaporation, volatilization, ignition, and complete combustion. Ash residue is discharged through an outlet at the kiln’s tail end, while the generated flue gas proceeds to a secondary combustion chamber. Here, it mixes with secondary combustion air to ensure thorough burning, leading to the safe and compliant discharge of exhaust gases. Key features of rotary kiln incinerators include their broad adaptability to various wastes, ease of operation and maintenance, and extended service life.

Reviews

There are no reviews yet.