Core Builder for Plate Bar Heat Exchanger

For vacuum brazing Aluminum Plate Bar Cooler, traditional radiator core assembly method is to adopt the width adjustable fixed high baffle on the cast iron platform. After core assembly, professional person has core trimming and use heavy stainless cast steel clamps and long bolts, nuts to fix core. This method is time-consuming and labor-intensive, and cannot make full use of the heating space of Vacuum Brazing Furnace.

Place Of Origin: China

Status: New

Productivity: 100 Units /Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100 sets/ Month

Port: Shanghai ,Ningbo

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW,FCA

Packaging & Delivery

-

Selling Units:Set/Sets

-

Package Type:Pallet/Case

-

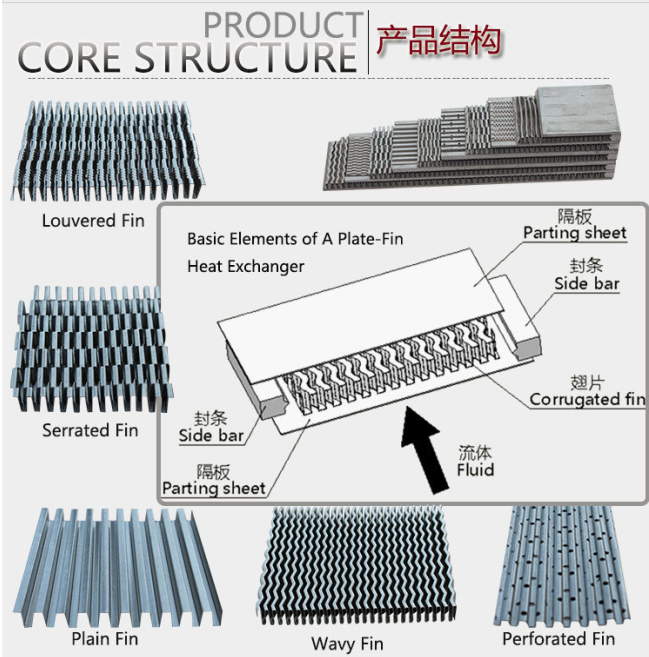

For vacuum brazing Aluminum Plate Bar Cooler, traditional radiator core assembly method is to adopt the width adjustable fixed high baffle on the cast iron platform. After core assembly, professional person has core trimming and use heavy stainless cast steel clamps and long bolts, nuts to fix core. This method is time-consuming and labor-intensive, and cannot make full use of the heating space of Vacuum Brazing Furnace. In order to improve the production efficiency of core assembly and reduce energy consumption, Core Assembly Machine technology has gradually entered the field of aluminum plate fin heat exchanger, plate bar cooler, radiator, which greatly speeds up the core assembly efficiency and increases the loading capacity of brazing furnace. Plate bar cooler core assembly machine is suitable for assembling plate bar cooler cores of various specifications. The core builder for plate bar cooler can easily and flexibly adjust the length, width and height of the cooler core. The Core Builder for Plate Bar Heat Exchanger can save manpower and time, improve production efficiency and furnace loading amount to save energy consumption.

-

Plate Bar Cooler Core Builder Main Advantages:

-

(1) Realizing the core assembly and core shaping at same platform.

-

-

(2) Reducing the core shaping difficulty and saving core shaping time.

-

-

(3) Keeping core flat, without distortion so that improve the core brazing quality.

-

-

(4)Adopting new type fixtures instead of heavy stainless cast steel clamps so that increase the furnace's loading radio.

-

-

The plate and bar core builders have been widely used in plate Bar Heat Exchanger factories which greatly improves the production efficiency and save the labor cost.

-

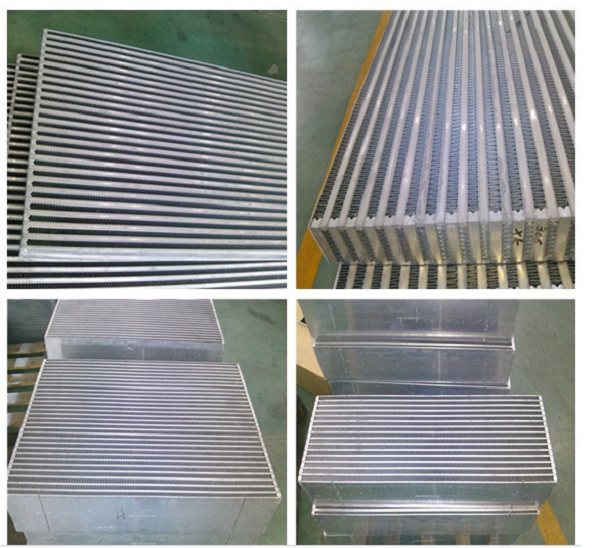

Aluminum Plate Bar Cooler Cores:

radiator core. The Plate Bar Cooler Core Assembly Machine can save manpower and time, improve production efficiency and furnace loading amount to save energy consumption.

-

-

-

The plate and bar builders have been widely used in plate Bar Heat Exchanger factories with below main advantages.

-

1) Finish the core assembling and shaping at one place.

-

2)Save the core shaping time and avoid the core moving of many times.

-

3) Increase the furnace's loading radio.

-

4) Improve the brazing quality.

-

Besides core assembly machine, we specialize in supplying the heat exchange production equipment including Fin Machine and fin mold, Supersonic Cleaning Machine, vacuum brazing furnace and more.

Related products

-

BF500C BF630C High Precision Edm Wire Cut Machine

Contact UsRobust frame with “C” mast.

With height adjustable diamond guider.

Four axes independent (X/Y/U/V) work;

Taiwan linear rail, Grade P or H, Ball screw. C2 or C3.

Special Tensioning mechanism for molybdenum wire, keep stable cutting.

Stepper motor is standard, Servo motor is optional.

Tolerance can keep in 0.005mm, Roughness Ra 0.8. -

PP PE HDPE LDPE LLDPE Film Waste Recycling Pelletizing Machine Pelletizer Granulator

Contact UsThis is multifunctional small pelletizing line. It is used to recycle various leftovers, such as PP, PE, HDPE, LDPE, PVC, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

3MK144 CNC automatic outer ring track grinder for ball bearing

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 1900mm*1350mm*1880mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board -

Digital-control Fluid Injection / Filling system

Contact UsFSH-SK10 product series is one of the high efficiency, high precision and high reliability intelligent digital-control dispensing system in high flow. FSH-SK10 is the top choice for automated fluid filling systems and intelligent factory production lines with high-capacity injection pump.

Reviews

There are no reviews yet.