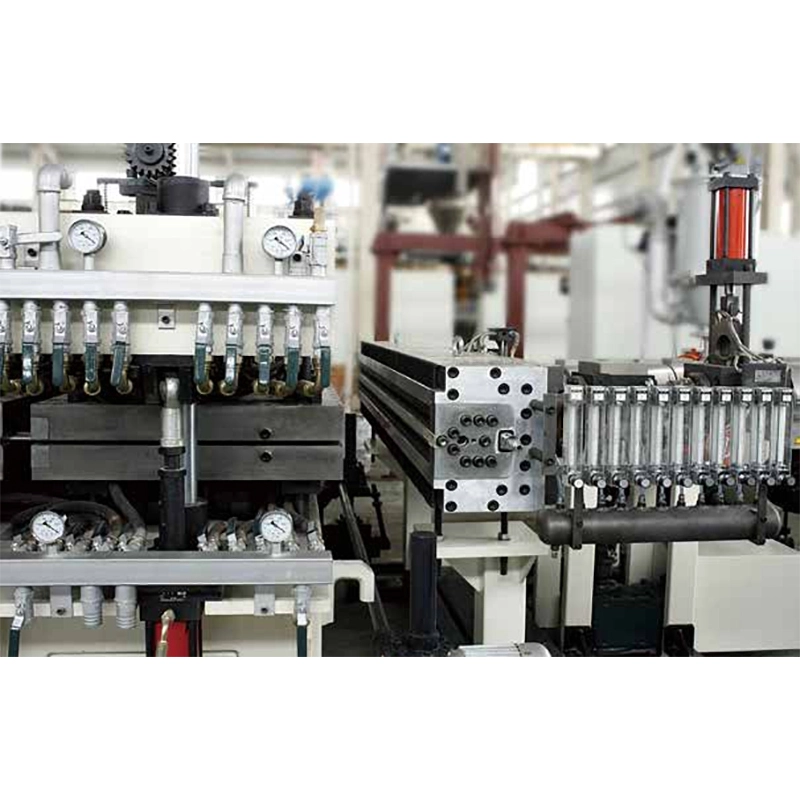

Hollow Cross Section Plate Die Series

PC hollow plate used widely in constructions and decorations.The hollow grid plate die and feedblock can make UV protection on both sides.

Different design can meet the different requirements of products, general polycarbonate

hollow plate whose thickness is between 4-25mm, multi-layers plate such as H-cross

section, X-cross section etc, the thickness of some can reach 36mm, and the UV layer can

be coated.

The PP, PE hollow grid plate produced by special dies are light weighted, dampproof and

have a high impact strength, which is widely used as advertising light panel, exhibition upholster, carry box etc.The thickness-range is 2-12mm and the width is 1200-2200mm.

FAQ

1. Q: Why should you choose Suzhou Jwell?

A: We follow Germany type of business heading as the worldwide reliable supplier of plastic extrusion line. We have already provided more than 5000 lines located in all countries because we are providing the lastest technology, qualified machine, reliable component and best after-service. 300 Engineers are travelling in the world throughout year for installation and test of machine, the after-service are free and availble forever. That's why we grow up from 10 staff company to 3500 staff Pioneer of Chinese extrusion machine supplier. Our products are spread all of China and also export to Russia, India, Korea, Indonesia, Middle East, Africa and south America, Spain, Italy, ect. We are received good appraisement from them.

“Excellent Quality and Perfect Product” is JWELL quality guidance, is the direction of the whole company’s member.

“Honesty” is our core thought to make “ Long life JWELL”.

2. Q: How much does it cost?

A: Please fill in your specific requirement in the bottom blank and sent to us, so that we could make a detail quotation for you.

3. Q: How about your after-sale service?

A: When the machines are ready and be sent to your factory, we will sent our engineers to your factory to help your worker to de the installation and train your workers. Above all, we have the maintenance engineers all over the world, who are always ready to go to our customer's factory and provide them with the best after-sale service.

Suzhou Jwell is a Plastic Machinery provider. The company has won unanimous praise. We look forward to further cooperation with you! Welcome to contact us!

4. Q: What is the warranty period, and do you offer global after-sales support?

A: The standard warranty covers 12 months for the whole machine. Suzhou JWELL has 30+ service centers worldwide, with a guaranteed 48-hour response time for emergencies.

5. Q: Can we test machine or produce small batches of samples?

A: Yes! Our Suzhou factory offers test runs—clients may bring their own materials, and we’ll provide a production report with detailed data.

Related products

-

Digital-control Fluid Injection / Filling system

Contact UsFSH-SK10 product series is one of the high efficiency, high precision and high reliability intelligent digital-control dispensing system in high flow. FSH-SK10 is the top choice for automated fluid filling systems and intelligent factory production lines with high-capacity injection pump.

-

Used NSC Schlumberger GC14 Gilling Machine

Contact UsYear: 1996

Spinning production line

Mixed strip: GC15 barrel diameter 1000 * 1200mm, 1 head and 1 barrel, automatic barrel change

One stitch: GC14 cylinder diameter 1000 * 1200mm, 1 head and 1 barrel, with self leveling and automatic barrel changing

Two needles: GC14 cylinder diameter 700 * 1200mm, two heads and two barrels, automatic barrel changing

Three needles: GC14 cylinder diameter 600 * 1200mm, 4 heads, 2 barrels, automatic barrel change

According to your requirements, we can transform it into a suitable size for your production needs! -

3MK2310B CNC Automatic Outer Ring Track Grinder for Tapered Roller Bearing

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 2100mm*1750mm*2030mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board -

FSH-MIC Micro Fluid Injection / Cleaning Pump

Contact UsFSH-MIC high-precision fluid point-to-liquid/cleaning pump integrates the driver chip into the motor, no controller is needed, only external IO signal is needed to trigger, and the point/subassembly can be completed according to the specified program. The system design is flexible, convenient for system integration, and reduce cost.

Reviews

There are no reviews yet.