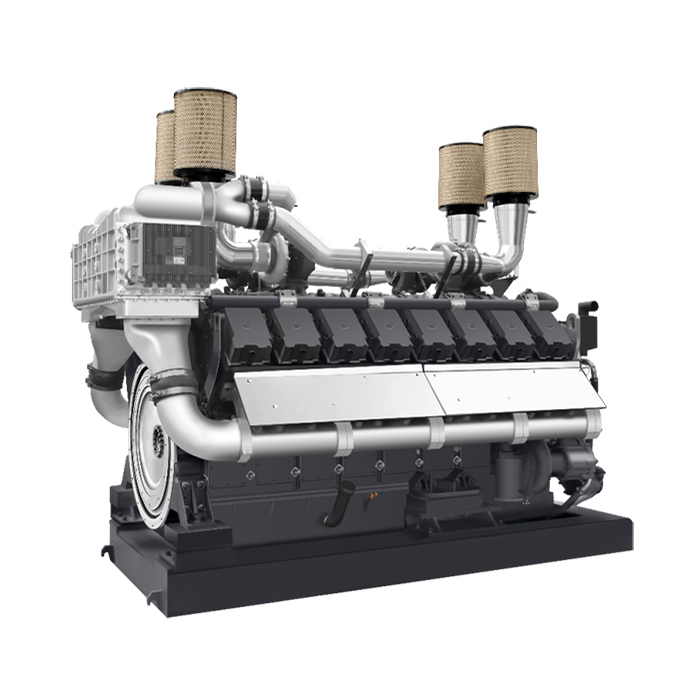

LEIQING Series High Speed Diesel Engines (1680~2660kW)

LEIQING Series High Speed Diesel Engines feature modular design for versatility and high reliability. Forged steel crankshaft, 4 valves per cylinder, and integrated cooling pistons extend service life. Quiet operation with reduced vibration. High-pressure common-rail fuel injection ensures strong power and optimal fuel economy. Equipped with high and low temperature circulating pumps for efficient cooling.

● Industrial Diesel Engine

● Power: 1680~2660kW

● rpm: 1500

https://www.wandipower.com/LEIQING-Series-High-Speed-Diesel-Engines-1680-2660kW.html

Features

● The high speed diesel engine comes with a modular design, featuring versatility for a wide range of applications, high reliability, ease of maintenance, high safety, etc.

● The crankshaft is made of forged steel, providing improved fatigue strength and wear resistance; Cooling type oscillating piston is integrally cast for extended service life.

● The front-mounted double-layer gear transmission mechanism reduces vibration, allowing for quiet running.

● The diesel engine is designed with 4 valves per cylinder with one head to achieve improved performance. Featuring the cylinder head with low swirl ratio ensures the uniformity of the air/fuel mixture, good combustion performance, low oil consumption.

● The high speed engine is equipped with two high and low temperature circulating pumps for the cooling system, which are used respectively for cooling high temperature coolant and low temperature air inlet.

● Using high-pressure common-rail fuel injection system with electronic control system in diesel engine realizes precise control in time, quantity and pressure. This makes diesel engine features strong power, optimal fuel economy, and precise emission control.

Parameters

|

Model |

Bore×Stroke (mm) |

Displacement (L) |

Rated Speed (r/min) |

Rated Power (kW) |

Max. Power (kW) |

Min. Fuel Consumption(g/kW•h) |

Oil Consumption (g/kW•h) |

Exhaust Temperature (℃) |

|

WD628E3TWD168 |

160×195 |

62.73 |

1500 |

1680 |

1848 |

195 |

≤0.48 |

≤700 |

|

WD628E3TWD182 |

160×195 |

62.73 |

1500 |

1820 |

2002 |

195 |

≤0.48 |

≤700 |

|

WD628E3TWD201 |

160×195 |

62.73 |

1500 |

2018 |

2220 |

195 |

≤0.48 |

≤700 |

|

WD708E3TWD222 |

170×195 |

70.82 |

1500 |

2220 |

2442 |

195 |

≤0.48 |

≤700 |

|

WD708E3TWD241 |

170×195 |

70.82 |

1500 |

2418 |

2660 |

195 |

≤0.48 |

≤700 |

Applications

The versatility of our high speed diesel engines makes them ideal for a wide range of applications:

– Power Generation: Reliable base-load power for industrial and commercial facilities, suitable for use as a diesel engine for gensets.

– Pumping Systems: Efficient operation for water and oil pumping in various industries

– Construction Equipment: Powering heavy machinery in construction sites

– Data center: Ensure uninterrupted power supply to the data center

Advantages

Innovative Design of Industrial Diesel Engines

The LEIQING series industrial diesel engines are engineered with an integrated and modular concept. This ensures their versatility, reliability, maintainability, and safety in industrial applications. These engines are not only designed to enhance work efficiency but also to simplify the maintenance and repair process.

High Performance

As representatives of high speed diesel engines, the LEIQING series offers models with a rated speed of 1500 rpm. These engines provide continuous and stable output under various load conditions. This high speed performance makes the LEIQING series diesel engines excellent for industrial applications that require rapid response and high efficiency.

High-Efficiency Fuel Injection System

The LEIQING series diesel engines utilize an electronically controlled high-pressure common rail fuel injection system, which enables precise control of fuel timing, quantity, and pressure. This precise control not only improves fuel economy but also helps reduce emissions, meeting increasingly stringent environmental standards.

Optimized Cooling System Design

To ensure the stability of the machine during prolonged operation, the LEIQING series diesel engines feature a high and low-temperature dual water pump circulation cooling system. This design separately cools the engine's high-temperature coolant system and low-temperature intake cooling system, effectively reducing the operating temperature of the machine and extending its service life.

Related products

-

7000A 12V&24V Jump Starter for Truck Starting in -40°C

Contact UsConquer the coldest of temperatures with our Arctic Warrior 7000A 12V&24V Jump Starter.

-

25KVA/20KW 50HZ Diesel Generator With Cummins Engine

Contact UsAs a 25KVA 20KW diesel generator with Cummins engine exporter,EMEAN POWER provides reliable and efficient 25KVA 20KW silent diesel generators running at 50Hz.

-

Used NSC Schlumberger GC14 Gilling Machine

Contact UsYear: 1996

Spinning production line

Mixed strip: GC15 barrel diameter 1000 * 1200mm, 1 head and 1 barrel, automatic barrel change

One stitch: GC14 cylinder diameter 1000 * 1200mm, 1 head and 1 barrel, with self leveling and automatic barrel changing

Two needles: GC14 cylinder diameter 700 * 1200mm, two heads and two barrels, automatic barrel changing

Three needles: GC14 cylinder diameter 600 * 1200mm, 4 heads, 2 barrels, automatic barrel change

According to your requirements, we can transform it into a suitable size for your production needs! -

RO water Treatment

Contact UsThe reverse osmosis equipment passes the raw water through fine filters, granular activated carbon filters, compressed activated carbon filters, etc., and then pressurizes it through a pump, using a p

Reviews

There are no reviews yet.