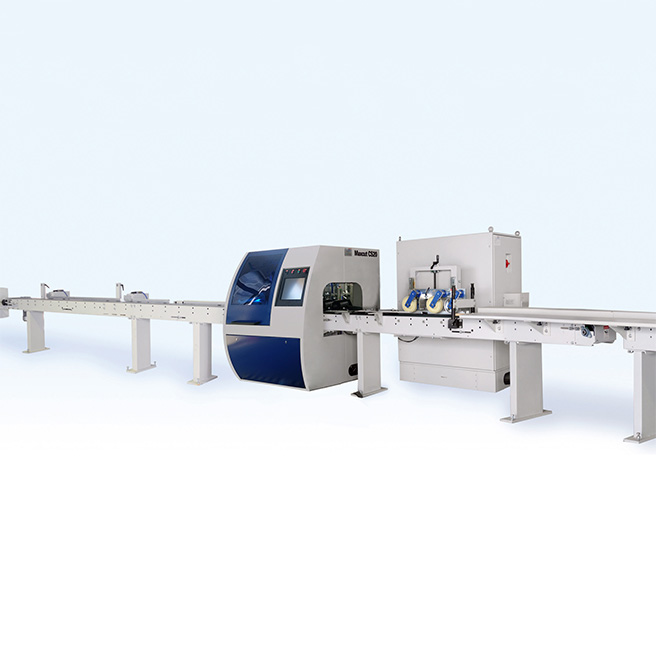

Optimizing Cross Cut Saw MAXCUT F30

Optimizing Cross Cut Saw MAXCUT F30 offers fully optimizing options for all industrial requirements. It is especially suitable for the wider timber processing.

OPTIMIZING CROSS CUT SAW MAXCUT F30

UNION BROTHER have developed series of optimizing cross cut saws, based on different requirement of wood working manufacturing process. From PLC control, computer software control, to intelligent system solutions. MAXCUT F30 is especially for “many lists with small numbers” factory.

Cross cutting is very crucial in wood machining process, the Optimizing Cross Cut Saw will bring a fundamental innovation compare with the manual cutting. It will reduce the timber waste and prevent the potential risks to the operators.

Advantages

● Remove the defeats (burl, crack, head and end) marked on the timber.

● To cut off after measure and optimize by computer software with high accuracy.

● To minimize the working load of the operators.

● To provide many optimizing modes, flexible for choose.

Applications

● Wood furniture

● Sofa manufacture

● Laminated wood manufacture

Related products

-

Rotary kiln incinerator

Contact UsRotary kiln incineration systems are widely adopted in the international industrial waste treatment sector, holding an approximate market share of 85% in this field. They are also recommended by China’s Ministry of Science and Technology and the National Environmental Protection Agency as the preferred furnace type in the National Industrial Waste Treatment Technology Policy. These systems can simultaneously handle sludge, industrial waste and waste with high moisture content. Solid waste is conveyed into the rotary kiln where it undergoes moisture evaporation, volatilization, ignition, and complete combustion. Ash residue is discharged through an outlet at the kiln’s tail end, while the generated flue gas proceeds to a secondary combustion chamber. Here, it mixes with secondary combustion air to ensure thorough burning, leading to the safe and compliant discharge of exhaust gases. Key features of rotary kiln incinerators include their broad adaptability to various wastes, ease of operation and maintenance, and extended service life.

-

PP PE HDPE LDPE LLDPE Film Waste Recycling Pelletizing Machine Pelletizer Granulator

Contact UsThis is multifunctional small pelletizing line. It is used to recycle various leftovers, such as PP, PE, HDPE, LDPE, PVC, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

-

RO water Treatment

Contact UsThe reverse osmosis equipment passes the raw water through fine filters, granular activated carbon filters, compressed activated carbon filters, etc., and then pressurizes it through a pump, using a p

-

BF500C BF630C High Precision Edm Wire Cut Machine

Contact UsRobust frame with “C” mast.

With height adjustable diamond guider.

Four axes independent (X/Y/U/V) work;

Taiwan linear rail, Grade P or H, Ball screw. C2 or C3.

Special Tensioning mechanism for molybdenum wire, keep stable cutting.

Stepper motor is standard, Servo motor is optional.

Tolerance can keep in 0.005mm, Roughness Ra 0.8.

Reviews

There are no reviews yet.