Solid-liquid incinerator project for Ningxia

This project is a 10,000 tons/year hazardous waste incineration device for Ningxia, which is used for incineration and treatment of hazardous waste produced by our factory.

Automatic feeding system — automatic feeding system — Rotary kiln — liquid waste furnace — secondary combustion chamber — SNCR denitration system — Waste heat steam boiler — rapid cooling deacidification tower — dry spray tower (lime, activated carbon jet) — cloth bag dust collector — Induced draft fan — SCR denitration system — spray tower — packing spray tower — wet electric dust collector — smoke fontanel — discharge

Related products

-

Waste liquid and waste gas incineration device

Contact UsThe furnace volume of the combined incinerator is based on the exhaust gas generated by incineration, the comprehensive residence time is ≥4s, the high-temperature (1100℃) incineration treatment is ≥1100℃, and the high-temperature section residence time is ≥2.5s to ensure the removal efficiency of organic matter.

-

KPR Zeolite Rotary Concentrator

Contact UsUnder low temperature conditions, high air volume organic waste gas passes through the KPR Zeolite Rotary Concentrator, and VOC molecules adsorb its surface.

-

Coke Oven Gas Hydrogenation

Contact UsCoke oven gas is a flammable gas produced during the high-temperature, slow dry distillation of coal in the coke production process.

-

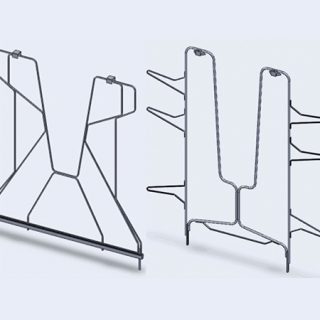

Hob

Contact UsIt is used Can-making/Metal sheet Painting and Printing Ovens. According to the specifications of the printed and coated products, a large number of C-shaped buckles and rollers (made of specialized food grade imported materials) are installed on the inner bracket and edge ears of the wicket, allowing the sheet (aluminum plate) to dry and run in a separate state from the wicket, effectively avoiding the problem of dot shaped scratches and burns in the printed and coated products.

Reviews

There are no reviews yet.