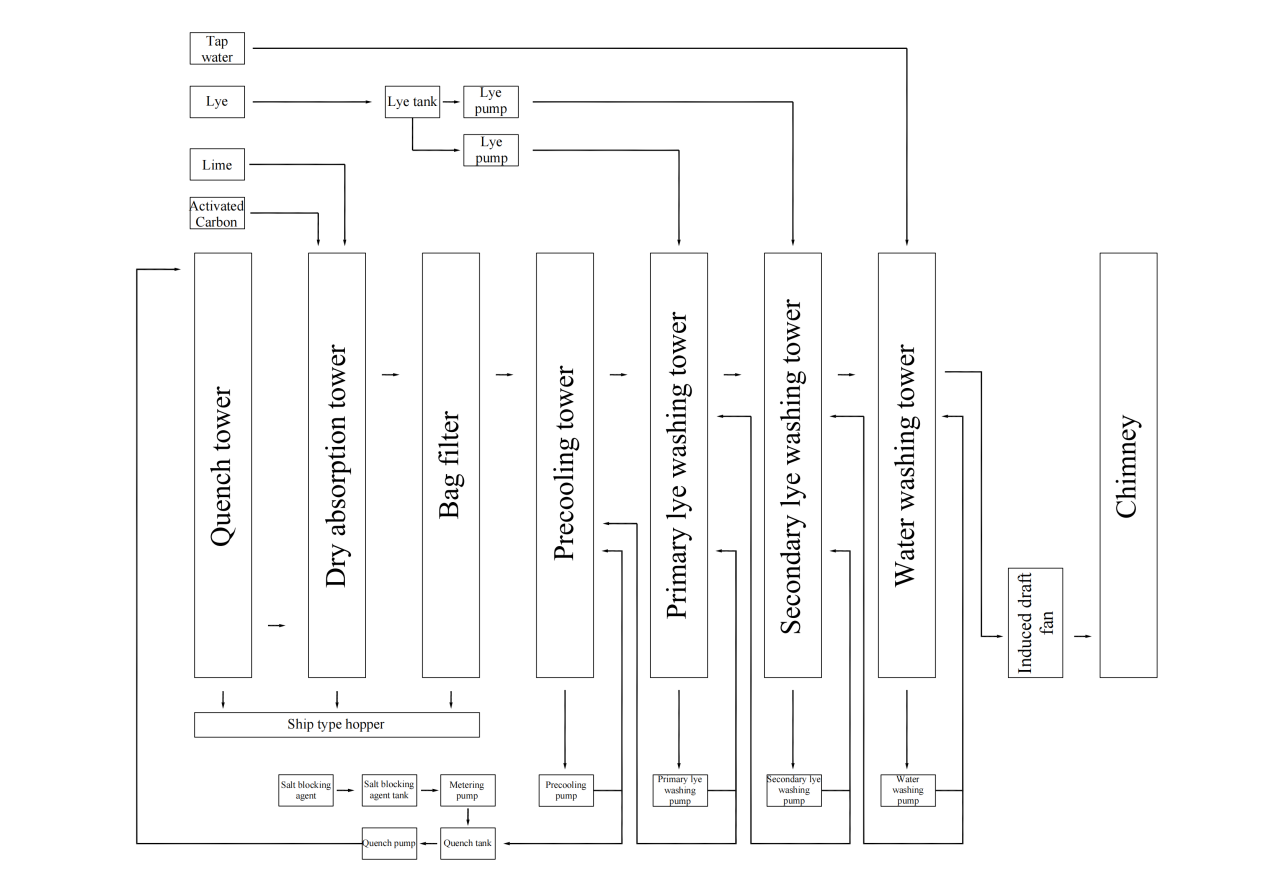

Waste liquid and waste gas incineration device

The furnace volume of the combined incinerator is based on the exhaust gas generated by incineration, the comprehensive residence time is ≥4s, the high-temperature (1100℃) incineration treatment is ≥1100℃, and the high-temperature section residence time is ≥2.5s to ensure the removal efficiency of organic matter.

Incineration is a high-temperature pyrolysis treatment technology. That is, a certain amount of excess air and the treated organic waste are subjected to oxidation combustion reaction in the incinerator, and the harmful and toxic substances in the waste are oxidized and pyrolyzed at a high temperature of 1100°C and destroyed. It is a treatment technology that can simultaneously achieve the harmlessness, reduction and resource utilization of waste.

Related products

-

DF-03 HT Modified Starch

Contact UsDF-03 is modified starch by inserting hydration groups and high temperature stabilizer to improve the water solubility and temperature resistance (up to 135 ℃). And ensure its good fluid loss performance under both low and high temperature. DF-03 is an environmental friendly, low viscosity, salt resistance (up to saturation) filtration reducer. Its recommend dosage is 1.0%-2.0%.

-

KSDM-4.0 Downdraft Grinding Dust Collector

Contact UsFeatures:

● Low noise

● Stable performance

● Easy operation and use High purification efficiency

● Meeting indoor emission standards Reasonable structure design

● Low resistance loss -

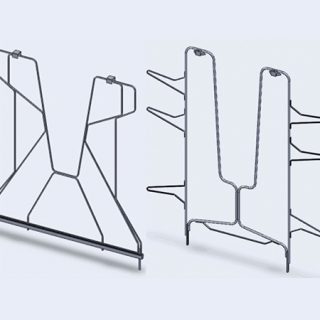

Hob

Contact UsIt is used Can-making/Metal sheet Painting and Printing Ovens. According to the specifications of the printed and coated products, a large number of C-shaped buckles and rollers (made of specialized food grade imported materials) are installed on the inner bracket and edge ears of the wicket, allowing the sheet (aluminum plate) to dry and run in a separate state from the wicket, effectively avoiding the problem of dot shaped scratches and burns in the printed and coated products.

-

Hazardous Waste Incineration Device for Hubei Shengling

Contact UsThis project intends to build a hazardous waste incineration device of 80t/d wastewater, 6.0t/d waste liquid, 11000Nm3/h waste gas and 500kg/d solid waste of Hubei Shengling Technology Co., Ltd., which is used to incinerate and treat hazardous waste generated by the plant.

Reviews

There are no reviews yet.