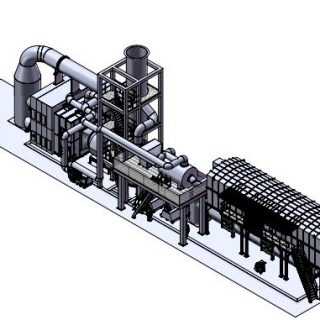

KSDM-4.0 Downdraft Grinding Dust Collector

Features:

● Low noise

● Stable performance

● Easy operation and use High purification efficiency

● Meeting indoor emission standards Reasonable structure design

● Low resistance loss

Introduction:

The downdraft grinding dust collector can realize the working mode of bottom suction to absorb and purify the dust generated during the polishing process. The front bottom suction is set according to the physical characteristics of the dust. The combination of top air supply and bottom suction can not only achieve the purpose of absorbing dust, but also bring fresh breathing air to the staff, thereby effectively protecting the working environment of the staff.

Parameters:

| Model | KSDM-4.0 |

| Inlet Air Flow | 4000±200m³/h |

| Motor Power | 4kW |

| Power Supply | 3x380V/50Hz |

| Filter Material |

Spunbond polyester |

| Filtration Area | 24㎡ |

| Filtration Efficiency | >99.9% |

| Filtration Precision | ≥0.3μm |

| Filter Cartridge | 2 Pcs |

| Cleaning Method |

Automatic cleaning |

| Compressed Air | 0.5~0.6MPa |

| Noise Level | ≤75±5 dB(A) |

| Dimension (WxDxH) | 1600×1150×1900mm |

| Working table (WxDxH) | 1515×1000×850mm |

| Weight | 650±15kg |

Options & Accessories:

Independent electric control cabinet

Frequency converter

Explosion proof device

Anti-static filter cartridge

Cellulose filter cartridge

Applications:

Downdraft grinding dust collector

Customized grinding dust collector

ATEX grinding dust collector case

Related products

-

RTO regenerative thermal oxidizer for removing VOCS

Contact UsRTO is an air pollution control system which collecting the exhausted air through the safety air valve into the oxidation bed with the temperature over 820℃ to oxidation the organic waste gas into carbon dioxide and water.

It is used

1. Industrial and mining conditions with high and low concentrations of organic solvents in the treatment of emitted gases

2. Industrial and mining conditions with requirements for the collection and treatment of unorganized emissions

3. Equipment conditions without waste heat utilization value -

Waste liquid and waste gas incineration device

Contact UsThe furnace volume of the combined incinerator is based on the exhaust gas generated by incineration, the comprehensive residence time is ≥4s, the high-temperature (1100℃) incineration treatment is ≥1100℃, and the high-temperature section residence time is ≥2.5s to ensure the removal efficiency of organic matter.

-

The 60t/d Hazardous Waste Incinerator Project of Jiangxi Brothers Pharmaceutical Co., Ltd.

Contact UsThe project plans to build a 60-ton-day hazardous waste incineration device of Jiangxi Brothers Pharmaceutical Co., LTD., for the incineration and treatment of the hazardous waste generated by the plant.

-

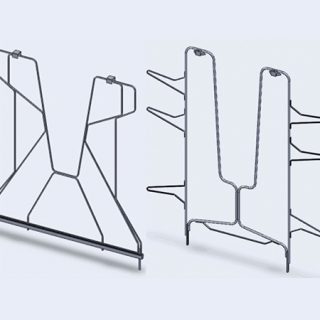

Hob

Contact UsIt is used Can-making/Metal sheet Painting and Printing Ovens. According to the specifications of the printed and coated products, a large number of C-shaped buckles and rollers (made of specialized food grade imported materials) are installed on the inner bracket and edge ears of the wicket, allowing the sheet (aluminum plate) to dry and run in a separate state from the wicket, effectively avoiding the problem of dot shaped scratches and burns in the printed and coated products.

Reviews

There are no reviews yet.