The fast cylinder plays the role of fast mold transfer in large injection molding machines. Due to the fast running speed, the requirements for straightness are relatively high. The back cover, hinge shaft and cylinder are welded into one piece. Piston rod high frequency treatment.

| Cylinder name | Bore range | Travel range | Rated pressure (Mpa) | Installation method |

| Fast oil cylinder (welding type) | 63~190 | 1100~4800 | 25 | Hinge type + universal bearing |

1. Tie rod type, the front and rear covers are fixed by a tie rod. Limited by

the tie rod, it is generally suitable for small oil cylinders. Although the wall

thickness is the thinnest, under the same specification, the external dimensions

will be too large, and the space waste is serious.

2. Bolt type, the front and rear covers and the cylinder barrel are connected

by bolt groups. The required thickness of the cylinder is the largest, and the

raw materials are relatively wasteful. Generally suitable for large

cylinders.

3. Threaded type, the front and rear covers and the cylinder barrel have

large threads, and are connected by threads. The required thickness is smaller

than the bolt type, but it is still thicker, and a large nut is required to

ensure the assembly direction. Generally suitable for large long cylinders

4. Welding type, the back cover and the cylinder are welded into a whole, the

wall thickness of the cylinder is relatively thin, and the whole is relatively

compact. The material cost is not high, but the processing is the most difficult

and the processing cost is the highest.

Related products

-

Full Shift Cylinder (Tie Rod Type/Thread Type)

Contact UsWidely used for moving whole part of machines with low speed.

-

Yaw pitch gear

Contact UsWind turbine gears are an indispensable part of wind turbines. Their function is to convert the rotation speed of the wind rotor into the speed required by the generator, thereby generating electricity. The function of wind turbine gears is not simply to transmit power, but also involves the efficiency, reliability and life of wind turbines. It can improve power generation efficiency, stabilize operation, extend life, and reduce maintenance costs. With the continuous development of wind power generation technology, the role of wind turbine gears will become more and more important.

-

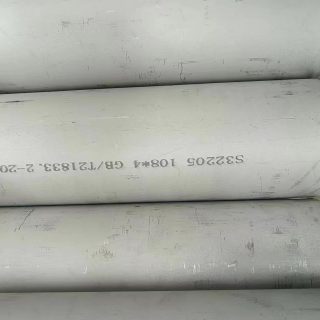

Duplex S32205 Seamless Pipe ASTM A790 Annealed Pickled

Contact UsSpecification: ASTM A790/A790M

Name: Duplex SS S32205 Seamless Pipe

Grade:S32205

Process: Seamless

Delivery Condiction:

1. Annealed, Pickled

2. Bright Annealed -

High quality rotary reducer gears

Contact UsThe company’s main products are high precision involute cylindrical gears,We specialize in manufacturing of gears products such as spur gear,helical gear, herringbone gear, external spline, internal spline, crownedgear, synchronous pulley, sprocket.

Reviews

There are no reviews yet.