KSZ-3.0D1/D2 welding exhaust hose

KSZ-3.0D1/D2 welding exhaust hose Features:

● High efficiency custom aluminum impeller

● Self-supporting & self-positioning suction hood

● Durable flexible suction arm, high temperature resistance & flame retardant & abrasion resistance

● Easy to replace and clean filters, no frequent maintenance is required

● Imported filter material with high precision filtration

● Special designed dust cleaning device, automatic blow-back cleaning

● Siemens PLC smart control system, more intelligent and energy saving

● Integrated automatic fire extinguish system

KSZ-3.0D1/D2 welding exhaust hose Introduction:

KSZ series multifunctional soldering exhaust hood adopts intelligent PLC system, displays real-time operating parameters, and can realize automatic cleaning according to the monitoring of differential pressure sensor. Its freely movable suction arms can be easily extended or rotated 360°, and its suction hood is also simple to position above any welding workstation without any external support, which allowing welders to position the hood wherever it’s needed. Meanwhile, its temperature monitoring and integrated automatic fire extinguish system make it safer to use.

Parameters:

|

Model |

KSZ-3.0D1/D2 |

|

Fan Air Flow |

4000 ± 100m³/h |

|

Inlet Air Flow |

2800m³/h |

|

Motor Power |

3.0kW |

|

Power Supply |

3×380V/50Hz |

|

Filter Material |

Polyester + PTFE |

|

Filtration Area |

20㎡ |

|

Filtration Efficiency |

≥99.9% |

|

Filtration Precision |

≥0.3μm |

|

Filter Cartridge |

2pcs |

|

Cleaning Method |

Automatic |

|

Compressed Air |

0.5~0.6MPa |

|

Noise Level |

≤74± 5dB(A) |

|

Dimension (W×D×H) |

800×800×1633mm |

|

Weight |

266 ± 10kg |

Options & Accessories:

PLC Intelligent control system

Frequency converter

Remote switch

Explosion proof device

Anti-static filter cartridge

Application:

Welding fume Filtration, Welding fume Killer System

Robotic Welding Fume Extraction & Dust Extraction

Soldering and Fume Filtration

Laser Fume Filtration

Hazardous Fume / Dust Filtration / Odor Removal

Medical Lab Gas / Fume / Dust Filtration

Pharmacy lab Dust Filtration

Custom Made Ducting with Exhaust Systems

welding exhaust hoods effect

welding exhaust hoods, a cover type device for removing harmful substances from the air. It is used to collect and guide harmful substances such as flue gas, toxic gas and dust, so as to remove them directly or after purification. SOLDERING EXHAUST HOOD is generally installed on the upper or side of the place where the harmful substances are generated, and the harmful substances are discharged through the welding exhaust hose.

Related products

-

Zwitterionic Polyacrylamide

Contact UsThe zwitterionic polyacrylamide is formed by copolymerization of the cationic monomer, acrylamide monomer, and hydrolysis agent.

-

Hob

Contact UsIt is used Can-making/Metal sheet Painting and Printing Ovens. According to the specifications of the printed and coated products, a large number of C-shaped buckles and rollers (made of specialized food grade imported materials) are installed on the inner bracket and edge ears of the wicket, allowing the sheet (aluminum plate) to dry and run in a separate state from the wicket, effectively avoiding the problem of dot shaped scratches and burns in the printed and coated products.

-

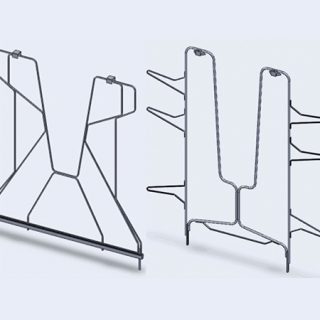

External Suction Arm

Contact UsFeatures:

● Persistent tightness

● Arm keeps position due to self-supporting design

● Fast operation due to particularly flexible adjustment

● User-friendly due to particularly smooth movement of the hood with one hand

● Various options to connect the exhaust arms to fans, stationary devices or via duct work to central extraction and filtration systems -

Waste liquid and waste gas incineration device

Contact UsThe furnace volume of the combined incinerator is based on the exhaust gas generated by incineration, the comprehensive residence time is ≥4s, the high-temperature (1100℃) incineration treatment is ≥1100℃, and the high-temperature section residence time is ≥2.5s to ensure the removal efficiency of organic matter.

Reviews

There are no reviews yet.