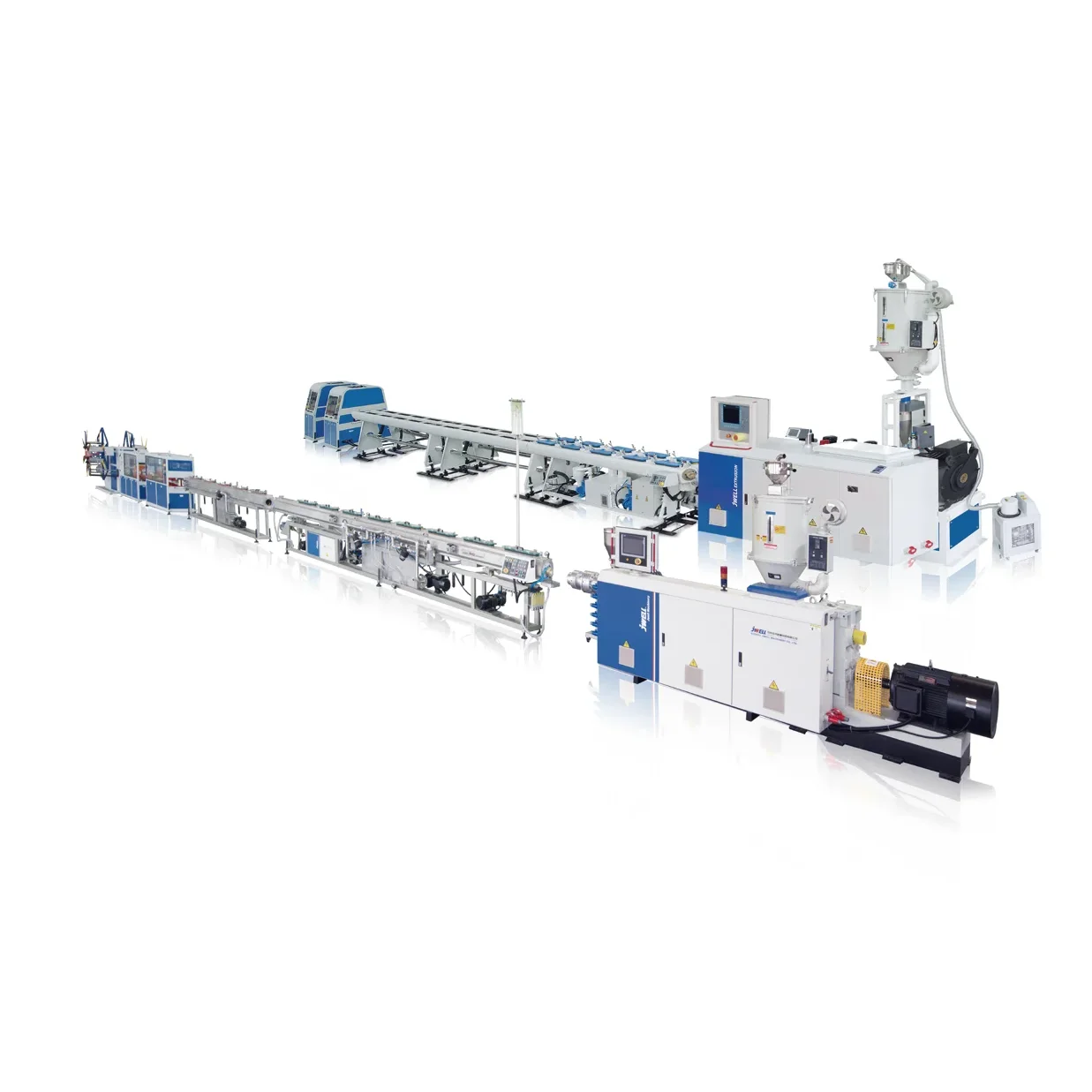

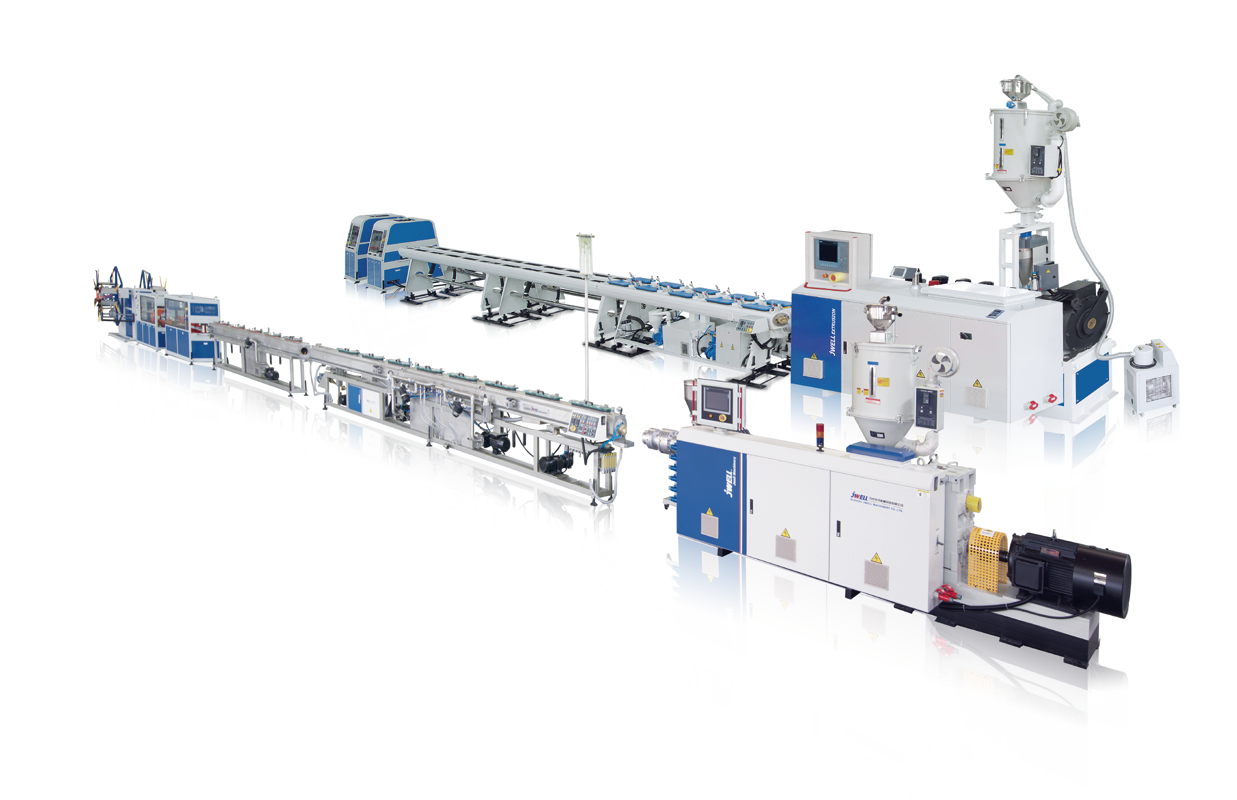

Small-diameter PE/PPR/PE-RT/PA Single-pipe, Dual-pipe High-speed Extrusion Line

The main screw adopts BM high-effiffifficiency type, and the output is fast and plasticized well. The wall thickness of pipe products is precisely controlled and very less waste of raw materials.

Product description:

Performance & Advantages:

The main screw adopts BM high-effiffifficiency type, and the output is fast and plasticized well. The wall thickness of pipe products is precisely controlled and very less waste of raw materials. Tubular extrusion special mold, water fifilm high-speed sizing sleeve, equipped with integrated flflow control valve with scale. Servo-controlled high-speed double-belt haul offff unit, supporting high-speed chipless cutter and winder, adapt to high-speed production operation. Dual pipe extrusion line can double the output and occupy less factory space.

Main Technical Parameters:

| Type | Pipe Spec (mm) | Extruder | Man power kw | Output (kg/h) |

| PE/PERT 75 | Φ20~Φ75 | JWS-H 60/40 | 110 | 380~420 |

| 90 | 350~400 | |||

| JWS65/33 | 75 | 200~240 | ||

| PPR 75 | Φ20~Φ75 | JWS-H 60/40 | 110 | 300~340 |

| 90 | 280~320 | |||

| JWS65/33 | 75 | 160~195 | ||

| PE/PERT 32 | Φ16~Φ32 | JWS-H 60/40 | 110 | 380~420 |

| 90 | 350~400 |

Note:The specifications are subject to change without prior notice.

Related products

-

7000A 12V&24V Jump Starter for Truck Starting in -40°C

Contact UsConquer the coldest of temperatures with our Arctic Warrior 7000A 12V&24V Jump Starter.

-

Oil-immersed transformer

Contact UsThe oil-immersed transformer is a new type of high-performance transformer with a more reasonable structure and better performance.

-

FSH-MIC Micro Fluid Injection / Cleaning Pump

Contact UsFSH-MIC high-precision fluid point-to-liquid/cleaning pump integrates the driver chip into the motor, no controller is needed, only external IO signal is needed to trigger, and the point/subassembly can be completed according to the specified program. The system design is flexible, convenient for system integration, and reduce cost.

-

NEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Contact UsNEW GLASS SODA MAKER BEST CARBONATOR(GLASS BOTTLE) NEW ARRIVALS SODA STREAM MAKER HOUSEHOLD SPARKLING WATER MAKER WITH GLASS BOTTLE

Reviews

There are no reviews yet.