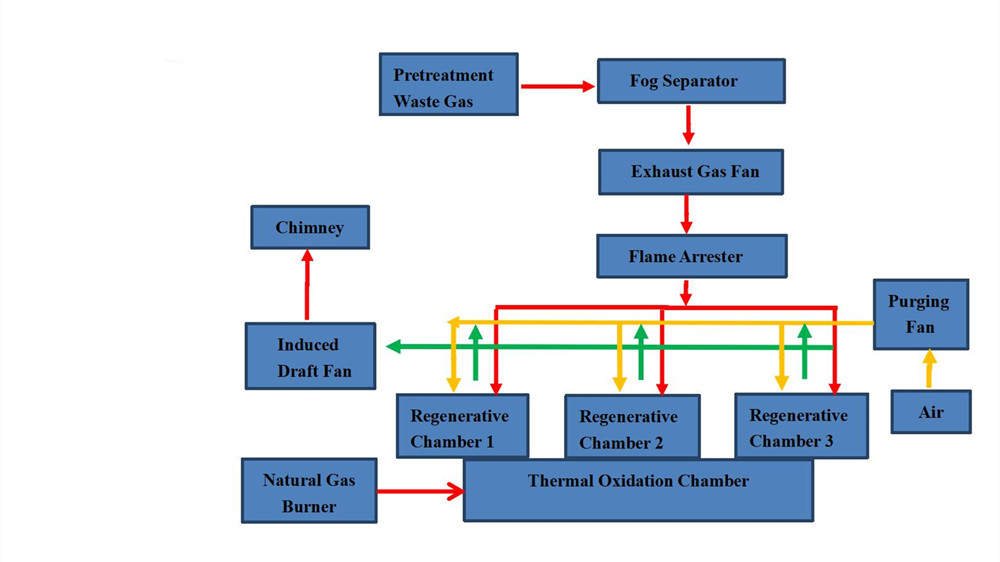

Regenerative thermal incinerator (RTO)

Coating, textile, pharmaceutical, chemical organic waste gas of low concentration, big air volume;

Related products

-

The 60t/d Hazardous Waste Incinerator Project of Jiangxi Brothers Pharmaceutical Co., Ltd.

Contact UsThe project plans to build a 60-ton-day hazardous waste incineration device of Jiangxi Brothers Pharmaceutical Co., LTD., for the incineration and treatment of the hazardous waste generated by the plant.

-

Coke Oven Gas Hydrogenation

Contact UsCoke oven gas is a flammable gas produced during the high-temperature, slow dry distillation of coal in the coke production process.

-

KSZ-3.0D1/D2 welding exhaust hose

Contact UsKSZ-3.0D1/D2 welding exhaust hose Features:

● High efficiency custom aluminum impeller

● Self-supporting & self-positioning suction hood

● Durable flexible suction arm, high temperature resistance & flame retardant & abrasion resistance

● Easy to replace and clean filters, no frequent maintenance is required

● Imported filter material with high precision filtration

● Special designed dust cleaning device, automatic blow-back cleaning

● Siemens PLC smart control system, more intelligent and energy saving

● Integrated automatic fire extinguish system -

KSDM-4.0 Downdraft Grinding Dust Collector

Contact UsFeatures:

● Low noise

● Stable performance

● Easy operation and use High purification efficiency

● Meeting indoor emission standards Reasonable structure design

● Low resistance loss

Reviews

There are no reviews yet.