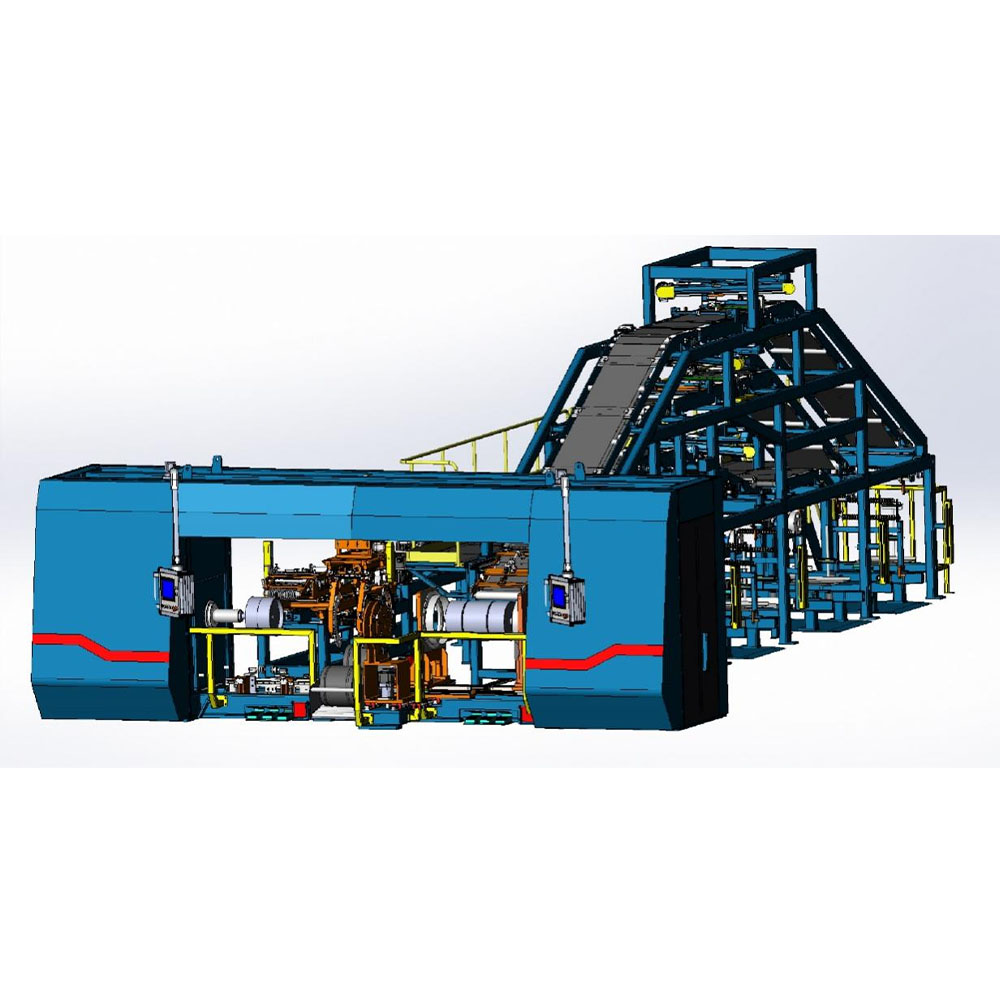

BTU High Efficiency Tire Building Machine

● Integral welded mainframe● Ball-wrapped carcass drum● 2-stage servo conveyor feeding to improve fixed length accuracy● Automatic fixed length and automatic cutting of each layer of material

Product Features:

High efficiency

-

Single cycle time 40s

-

Large roll I-shaped wheel

High quality

-

Integral welded mainframe

-

Ball-wrapped carcass drum

-

2-stage servo conveyor feeding to improve fixed length accuracy

-

Automatic fixed length and automatic cutting of each layer of material

-

Carcass joint detection (flash seam, wrong angle, big and small head, missing paste)

-

Ultrasonic cutter is used for tread, and the incision of the head and tail of the material is heated

High degree of automation and low labor intensity

-

Movable inner support wire placement seat

-

Automatic drum loading of steel wire ring

-

Automatic drum loading of carcass

-

Automatic tire unloading

-

Management of matching mode, one-button switching of specifications

High safety factor

-

Active safety rope, various photoelectric switch configurations

-

Anti-scalding and anti-pinch design

-

Upper and lower safety light curtains are configured on the operating side

-

Fault alarm prompt

Wide range of application

-

Applicable to the manufacture of motorcycle tires, agricultural tires and industrial special tires

Equipment Parameters:

|

Items |

Parameters |

|

|

Forming range |

14"-18" (08"-12", 12"-16") |

|

|

Equipment center height |

850-1000mm |

|

|

Rolling width |

0~350mm |

|

|

Rolling speed |

32.2mm/s |

|

|

Feeding form of tread, cord, liner |

Trolley type |

|

|

Lamination method of each layer of material |

Top mount type |

|

|

Inner rubber |

Width |

80mm-240mm |

|

Thickness |

0.4mm-1.4mm |

|

|

Cutting angle |

35° |

|

|

Cutting method |

Disc knife |

|

|

Curtain fabric |

Width |

150mm—380mm |

|

Thickness |

0.75mm-1.2mm |

|

|

Cutting angle |

24°—48° |

|

|

Cutting method |

Thermal cutting knife |

|

|

Buffer layer width |

50mm—240mm |

|

|

Tread rubber |

Width |

160mm—250mm |

|

Thickness |

5mm—15mm |

|

|

Cutting angle |

20°—30° |

|

|

Cutting method |

Ultrasonic cutter |

|

|

Overall efficiency |

≤40 seconds (liner × 1 + cord × 3 + tread × 1) |

|

|

Dimensions |

12000mm long × 6500mm wide × 3800mm high |

|

Equipment Accuracy:

|

Items |

Accuracy |

|

Levelness of guide rails of carcass drum |

≤ 0.05mm/m |

|

Radial runout of carcass drum main shaft |

≤ 0.1mm |

|

Axial runout of carcass drum main shaft |

≤ 0.1mm |

|

Radial runout of tread drum main shaft |

≤ 0.1mm |

|

Axial runout of tread drum main shaft |

≤ 0.1mm |

|

Coaxiality of carcass drum and tread drum |

≤ 0.5mm |

|

Coaxiality of carrying ring and tread drum |

≤ 0.5mm |

|

Coaxiality of carrying ring and carcass drum |

≤ 0.5mm |

|

Coaxiality of carrying ring and wire ring placement groove |

≤ 0.5mm |

|

Repeat positioning accuracy of carrying ring |

≤ ±0.2mm |

|

Inner rubber fixed length accuracy |

±2mm |

|

Inner rubber bonding accuracy |

±2mm |

|

Cord fixed length accuracy |

±2mm (Two yarns) |

|

Cord bonding accuracy |

3~5mm |

|

Cord single-side joint misalignment |

±3mm |

|

Tread fixed length accuracy |

±2mm |

|

Tread single-side joint deviation |

≤3mm |

Related products

-

Optimizing Cross Cut Saw MAXCUT F30

Contact UsOptimizing Cross Cut Saw MAXCUT F30 offers fully optimizing options for all industrial requirements. It is especially suitable for the wider timber processing.

-

Rotary kiln incinerator

Contact UsRotary kiln incineration systems are widely adopted in the international industrial waste treatment sector, holding an approximate market share of 85% in this field. They are also recommended by China’s Ministry of Science and Technology and the National Environmental Protection Agency as the preferred furnace type in the National Industrial Waste Treatment Technology Policy. These systems can simultaneously handle sludge, industrial waste and waste with high moisture content. Solid waste is conveyed into the rotary kiln where it undergoes moisture evaporation, volatilization, ignition, and complete combustion. Ash residue is discharged through an outlet at the kiln’s tail end, while the generated flue gas proceeds to a secondary combustion chamber. Here, it mixes with secondary combustion air to ensure thorough burning, leading to the safe and compliant discharge of exhaust gases. Key features of rotary kiln incinerators include their broad adaptability to various wastes, ease of operation and maintenance, and extended service life.

-

RO water Treatment

Contact UsThe reverse osmosis equipment passes the raw water through fine filters, granular activated carbon filters, compressed activated carbon filters, etc., and then pressurizes it through a pump, using a p

-

Capacity 1500ML Carbonated Drink Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1500ml

Bottle Type: CSD bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export.

Reviews

There are no reviews yet.